Developed ‘ResQ’, which removes micro static electricity

Performance to be evaluated with aims to begin supply in 2nd half of the year

Entering EUV market… diversifying business

NextIn is entering the field of extreme ultraviolet processing. They have developed equipment to remove ‘micro static electricity’, which can cause defects in microcircuits. EUV is a state-of-the-art semiconductor technology for realizing ultra-fine semiconductors.

NextIN recently developed micro static electricity removal equipment which can be used in EUV processes. This equipment, known as ‘ResQ’, will be evaluated for mass production by client companies with the goal of supplying it in the 2nd half of the year. This is the first time NextIn has released a product related to EUV.

The removal of static electricity in semiconductor manufacturing is essential. This is because semiconductors are damaged through sudden voltage. Currently, a method of neutralizing static electricity using air ions is used. However, this is mainly used in legacy processes around 100 nanometers.

As EUV processes have to create microcircuits under 10 nanometers, minute amounts of static electricity need to be removed. NextIn was able to use its own independent technology to create equipment that can neutralize micro static electricity. It is said that it is the result of joining forces with Zisys, which it acquired last year in April.

NextIn, which had been developing and selling pattern inspection equipment utilized in semiconductor pre-processes, plans to target the cutting-edge memory and foundry market with new equipment.

As EUV is utilized when creating micro system semiconductors, such as 5 nano and 7 nano semiconductors, as well as DRAM manufacturing, they are targeting their respective markets.

It is known that there is a high possibility of generating micro static electricity when forming thin films in the EUV process. It has been said that the level of static electricity which had previous not been an issue as become more of a risk as the width of the circuits have become smaller.

In addition to EUV equipment, NextIn also developed new models of inspection equipment with a 30% improvement in throughput compared to the previous generation. It is used to inspect ultra-fine pattern defects and particles.

In addition, they have completed the development of 3D memory inspection equipment and macro equipment which can quickly inspect the entire process and are about to be evaluated by client companies.

NextIn recently prepared new cleanrooms to expand their equipment manufacturing capacity. They plan to expand their equipment manufacturing capacity by more than two-fold.

It appears that NextIn plans to diversify their portfolio. It is their steppingstone to secure EUVs as their future money maker, in addition to their optical inspection equipment.

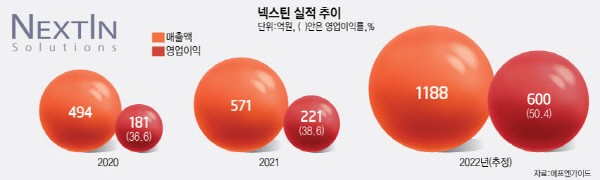

According to securities firms, NextIn’s sales last year are estimated to have doubled from the previous year to more than 100 billion KRW. There is attention on whether EUV equipment will become a new driving force.

A member of the semiconductor equipment industry said that, “Attempts to materialize R&D results will continue.”

By Staff Reporter Dongjoon Kwon (djkwon@etnews.com)