Applying ultra-high-strength 'borosilicate' glass

Securing productivity and price competitiveness… Supplying global companies

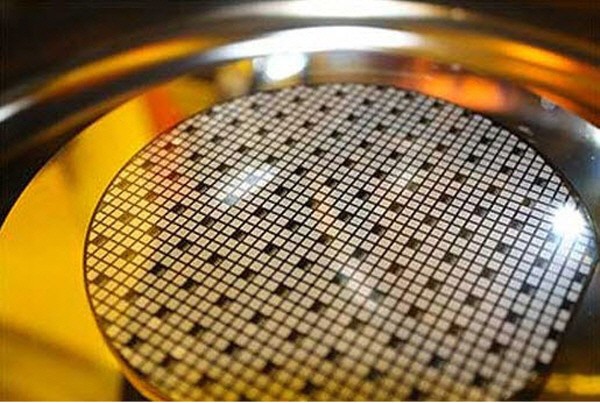

SCHOTT is a German special glass company that has succeeded in supplying glass carriers for cutting-edge semiconductor processes. Glass carrier is a protective material applied when transferring semiconductor wafers. It used to be made of silicon in the past.

On the 9th, SCHOTT Korea announced that it has started supplying glass carrier wafers for packaging to global semiconductor companies. The glass carrier is applied with ultra-high-strength special glass 'borosilicate', and applied to the 'Fan-Out-Wafer Level Package (FO-WLP)' process. FO-PLP (FO-WLP인가요?) is a packaging technology that implements high performance by taking the input/output terminal (IO: input output) that electrical signals enter and exit the chip.

An official from SCHOTT Korea said, “We satisfied aspects required by the advanced packaging process, such as the quality, performance, and process efficiency. We secured productivity and price competitiveness as well.”

Borosilicate is an ultra-high-strength glass that SCHOTT has been using as a packaging material for pharmaceuticals. It provides higher strength than ordinary glass and is more resistant to high temperatures.

By cooperating with a global customer, SCHOTT succeeded in applying the semiconductor packaging process. The application of new materials has been pushed forward since the product is superior in both performance and price compared to existing silicon-based products. Even though the specific customer was not disclosed, SCHOTT explained that it is conducting tests for the application of packaging materials with a new semiconductor customer.

Glass carriers are under the spotlight as being convenient to apply to wafer packaging processes. SCHOTT also plans to supply glass carriers to the manufacturing of power semiconductors for EVs. The glass product supply will be increased to secure a new growth engine for the future as semiconductors demands for EVs rise.

<Mini interview: Jung-hee Lee, CEO of SCHOTT Korea>

Jung-hee Lee, CEO of SCHOTT Korea, emphasized that “glass carriers will be a future growth engine.” The characteristics of the glass carriers are suitable for advanced semiconductor processes such as high heat resistance.

He claimed that there is a number of product demonstration tests in cooperation with domestic and foreign semiconductor companies. He expects that it can be used not only to protect wafers as a carrier, but also to be used as a high-performance semiconductor substrate material.

By cooperating with its German headquarters, SCHOTT Korea is enhancing its product technology team. This will allow the company to respond actively to customer requests.

CEO Lee led the growth in SCHOTT Korea’s business. Over the past five years, SCHOTT Korea has maintained double-digit growth. It has achieved high growth of 25% in the last two years. The sales in Korea are expected to reach 100 million euros (KRW 130 billion) this year.

CEO Lee emphasized, “By applying glass materials in areas such as EVs, autonomous driving lidar, and communication chips, we will generate new products that will support SCHOTT Korea for the next 50 years or more.”

By Staff Reporter Ji-woong Kim (jw0316@etnews.com)