Over 300 billion KRW to be injected by next year.

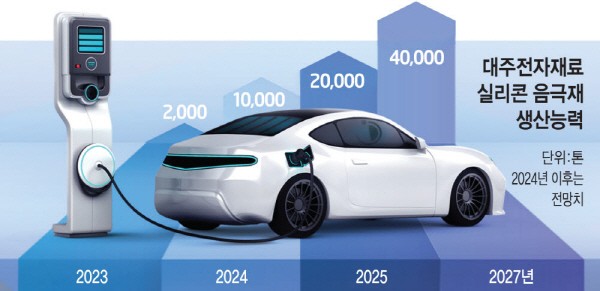

Goal to reach 40,000 tons by 2027… investments to continue

Daejoo Electronic Materials, Korea’s biggest silicon anode material company, is expanding its facilities. They will increase their silicon anode material production capabilities fivefold by the end of 2024. The large-scale expansion is a measure to respond to the rising demand of EV batteries.

Daejoo Electronic Materials decided to expand their current silicon anode composite oxide (Daejoo Metal Silicon Oxide, DMSO) production line with an annual production capacity of 2,000 tons to 10,000 tons by the end of next year and began investment. In addition to the 56.9 billion KRW announced through a recent public announcement, they made plans to increase their production capacity fivefold through additional investments next year. The total scale of investments is expected to easily surpass 300 billion KRW.

Silicon anode materials are products that are drawing attention as next-generation battery materials. It expands the charging capacity and improves the charging efficiency of batteries to shorten the charging times of EVs and enable them to run longer.

They began to emerge as silicon anode materials were first commercialized in Porsche’s EV, the Taycan. Daejoo Electronic Materials made the silicon anode materials, while LG Energy Solution made the batteries for the Taycan.

Currently, commercially available silicon anode materials contain about 5% of silicon. Battery and material companies are attempting to raise this ratio. With the development of 100% silicon ‘Pure Silicon’ as a leading example, such developments are being promoted to simultaneously improve EV battery performance and replace graphite, the main raw material of anode materials. This is because replacing natural graphite with silicon can help reduce the cost of batteries and improve resource dependency as well.

Daejoo Electronic Materials has stood out since 2019, as they began to supply LG Energy Solution with silicon anode materials. With the demand for EV batteries soaring starting with 5% silicon anode materials, it is currently growing. The company sales which were around 150 billion KRW in 2020 grew to 190 billion KRW by 2021, and it is estimated to have exceeded 200 billion KRW last year. In the conductive paste-centered business structure, silicon anode materials are establishing themselves as a new growth engine. It is known that Daejoo’s silicon anode materials have been applied to Hyundai Motor’s IONIQ 6 as well.

It has been reported that Daejoo Electronic Materials plans to expand their production capacity to 20,000 tons by 2025 and 40,000 tons by 2027 as mid to long-term plan goals in step with market growth. An official of the company said that, “We plan on continuous investment.” In addition to Siheung, where their headquarters are located, they are preparing to build a new factory in the Jeonbuk Saemangeum Industrial Complex. The construction of the factory in Saemangeum is set to begin this year.

The number of companies expanding into and increasing their investments into this field is increasing due to the growth potential of silicon anode materials. SK Materials Group 14, subsidiary of SK Materials specializing in silicon anode materials, recently began to invest in factory 2 before they began to operate factory 1, and POSCO Chemical and Hansol Chemical also threw their lots into the silicon anode material business.

Although silicon is attracting attention as a replacement for graphite, it has the problem of its volume expanding by over 4 times when it comes into contact with lithium ions. The question of whether this can be solved will be considered a difference in technical capacity.

Reporter Ji-woong Kim (jw0316@etnews.com)