Mobile ‘U-CeraConn’ replaces the existing LCP material

Strong heat resistance allows to transmit100 watts of high power

PhilTech first developed a high-performance ceramic-based USB connector for mobile devices. It is a fast USB charging port. It is expected to enhance heat conduction and heat resistance compared to existing liquid crystal polymer (LCP) to dramatically increase the charging speed.

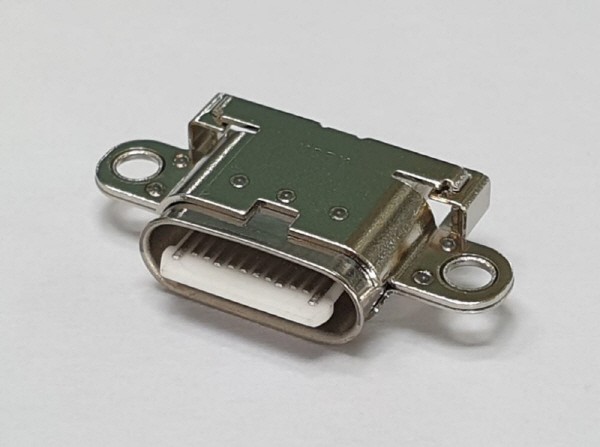

On the 21st, PhilTech announced, it has developed a USB-C type connector ‘U-CeraConn' that replaces the existing LCP. The ceramic connector is a USB-C charging port that uses Alumina Ceramic (Al2O3) instead of LCP, a kind of super plastic, and is a key component of smartphones. This is the first time to develop mobile parts using ceramic materials for connectors. Jaehyuk Choi, representative of PhilTech, said, “U-CeraConn will overcome the limitations of plastic materials and manufacturing methods of existing connectors, and will contribute to the development of industries that require high-speed data transmission and high-power transmission.”

PhilTech’s U-CeraConn uses high-purity ceramics to increase heat conduction by 80 times and enhance heat resistance hundreds of times compared to the previous product. It minimized dielectric loss due to electromagnetic waves, and enhances data transmission speed significantly.

It simplified the manufacturing process, and enableed to create various models on existing production lines. Manufacturing costs can be reduced by 30% compared to current connectors.

PhilTech explained that the USB connector satisfies 40 gigabit (Gbps) class high-capacity transmission speed, and 100 watt (W) class high-power transmission. It can achieve 10 times higher transmission speed than before.

PhilTech also secured U-Ceraconn reliability and waterproof performance. Traditional ceramic technology has been upgraded to enhance product performance.

A new method of directly printing pins on ceramic was applied to improve dimensional accuracy after breaking away from the conventional method of manufacturing connector pins from sheet metal. Forming fine lines enabled high-speed data transmission to optimize impedance matching.

An official from PhilTech said, “We have brought a rapid development and optimal performance with active support from the Korea Institute of Ceramic Engineering and Technology. We will develop various connector products that meet the requests of each mobile manufacturer with U-CeraConn as the basic model.”

PhilTech is a manufacturer of radio frequency (RF) equipment established in 2007. Based on the RF scanner equipment business, it is expanding its business area to mobile parts. PhilTech plans to develop not only mobile but also electronic components with USB ceramic connectors that replace existing LCP materials with ceramics.

By Staff Reporter Jiwoong Kim (jw0316@etnews.com)