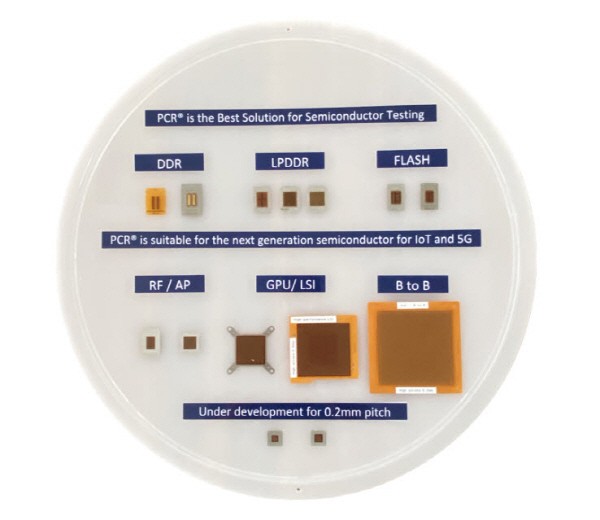

Tfe expanded its semiconductor test socket production capacity by 50%. The products that were only produced by its Japanese subsidiaries are being manufactured in Korea. The company is not only responding to the memory market, but also the rapidly increasing system semiconductor test market demand as well. Tfe builds a total portfolio of test parts from sockets to boards and changeover kits (COK) in order to significantly strengthen the driver.

Tfe built a research and development (R&D) center at its headquarters in Hwaseong-si, Gyeonggi-do, and created a semiconductor rubber socket production line. A rubber socket is a consumable part used to test whether a semiconductor chip functions normally. The current loss is reduced and the signal transmission speed is faster than that of the pogo pin, which was the current trend, which yielded high accuracy in tests.

Tfe acquired Japan’s JMT in 2019, and produced rubber sockets. The company secured additional production capacity, which was increased by 1.5 times with addition of domestic production line, and established a “two-track” production system in Japan and Korea. It is paving a way to increase the ability to respond to demand for semiconductor test sockets.

The increase in production capacity is due to the expansion of the system semiconductor test socket market as well as the memory market. The global test socket market last year was worth $1.764 billion according to TechInsight, and is projected to grow to $2.294 billion by 2026.

Sungjoo Moon, CEO of Tfe, said “We are targeting not only the memory test socket, but also the semiconductor test socket market, such as application processor (AP) for smartphones, the Internet of Things (IoT), and vehicles. We plan to continuously expand additional production infrastructure to meet market demand.” The ratio of memory and system semiconductors in the test socket market is 2:8.

Tfe provides a total solution for semiconductor test parts including rubber sockets, test boards, COKs, and burn-in boards. The semiconductor chip is inserted into a rubber socket, mounted on a test board, and inspected with a tester. COK is the device that transports the test board.

Tfe is the only company in Korea that produces, and supplies all the parts necessary for testing.

CEO Moon said, “Semiconductor manufacturers or OAST companies do not have to purchase products from multiple suppliers, which will significantly increase productivity. Tfe’s differentating strategy is maximizing the synergy between parts.” Tfe developed some test parts manufacturing equipment directly, established production line operation efficiency, and secured price competitiveness.

Tfe also entered the custom-made parts business in order to target the rapidly emerging market as the semiconductor industry shifts to a multi-variety, small-volume production system. It pre-orders and manufactures parts necessary for the production of various semiconductor products, and preemptively responds to market changes. Tfe recently established a second technology research institute, and is concentrating its R&D capabilities in order to manage the changes.

By Staff Reporter Dong-joon Kwon (djkwon@etnews.com)