Surging demand for batteries for EV

Delivery to the global No. 1 company one after another

The industry's highest and largest production of 50,000 tons per year

Goal of 1 billion KRW in sales by targ

We visited the SK nexilis copper foil factory in Jeongeup, Jeollabuk-do on the 11th, which was standing at the starting point of the secondary battery material upheaval. From a printed circuit board (PCB) copper foil production company in 1996 to a copper foil company for electric vehicle batteries in 2003, they have risen to become the No. 1 copper foil company in the world. Recently, as demand for batteries has surged focusing on EV, they were preparing to transform themselves into a global company once again. Jeongeup Factory, which boasts bold investment and world-class quality, is in the middle of this transformation.

◇The world's best copper foil company, SK's secret of 'Technology Investment'

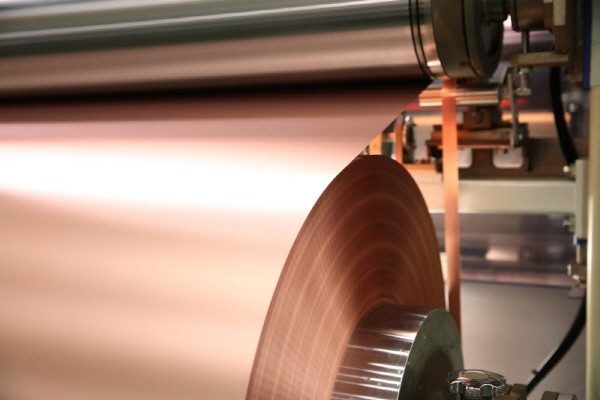

The 5thfactorycopper foil production line, which was unveiled on that day, is the core line of the SK nexilisJeongeup factory. Dozens of depositing machines (machines that make copper foil rolls) were rapidly rotating on the 129,000㎡ production line are which are producing copper foil that is 1/20 the thickness of hair.

The copper foil manufacturing process is simple. Copper foil for electric vehicle batteries is created through three steps; melting copper, plating, and cutting to the desired size. The main product is copper foil with a thickness of 4~6 micrometers(㎛), which is supplied to domestic and foreign EV battery makers.

Ki-Young Lim, head of production technology at SK nexilis, said, “The copper foil produced at 5th factory is 50,000 tons per year. The key technology is to make the product 'thinner', 'longer' and 'wider', which are now used for 1.5~2million EV, instead of 3~4g of copper foil used in information technology (IT) device back in the days." They can produce the industry's highest quality 4㎛ copper foil up to 77km long and 1.4m in width. More than 40 kg of copper foil is used for one electric vehicle. The 5th factory of SK nexilis is proud of their technological prowess enough to produce 6 tons of copper foil for the industry per one depositing machine.

Copper foil for Korea’s No. 1 LG Energy SolutionEV pouch battery, Japan’s No. 1 Panasonic cylindrical battery, and China’s No. 1 CATL prismatic battery are produced here. Theirtechnical skills are recognized in the world to the extent that they have been awarded a total of three times, including the Presidential Award, which is the highest award among the IR52 Award, the most prestigious technology award in Korea.

Jae-hong Lee, CEO of SK nexilis, said, “SK nexilis copper foil is by far the bestin the market since they are supplied to the top 5globalEV battery manufacturers.SK nexilisis the world's best copper foil technology company before SKC material affiliates.”

The competitiveness of the Jeongeupfactory’s products lies in the strict process management for last 26 years since the factory was established. In fact, after the manufacturing process is completed, the first inspection is performed by an automatic inspection device, and the secondary inspection is completed before supplying to the customer. An SKnexilis official said, "It is possible to inspect not only the thickness of copper foil, but also the quality of the product, so even minor defects can be caught."

In addition, the management of the product was strict enough to build cutting edge process for all copper foil processes, with manpower only in the process of packaging the product. Products that did not make the cut were recycled while trying to improve the product quality.

◇Target to achieve 1 trillion KRW in sales in 2023

The copper foil market is expected to grow at a CAGR of 40% to 750,000 tons by 2025. Tesla Model 3 uses about 40 kg of copper foil, but it is expected to increase to hundreds of kg as the number of large EV such as electric trucks and electric buses are increasing.

SK nexilis has secured a total production capacity of 50,000 tons with the 5th factory, and when the 6thfactory is completed, the production capacity will increase by nearly 60,000 tons. They are also planning to enter the US market within the year.

CEO Lee said, “Demand is rapidly increasing in the US, but there is no supply of its own. Since the US market is rising, we must preoccupy the customers with customized investment.”, to emphasized the importance of advancing into the US.The goal is to achieve 1 trillion KRW in sales next year. It is the largest sales challenge in the copper foil industry. SK on operates two of their own factories in Georgia, USA. As they have confirmed the construction of a joint plant for electric vehicle batteries with Ford, copper foil supply is unable to keep up with demand. SK nexilis emphasized that since the incorporation of SK Group, they have been constructing factories once a year on average, including factory 5th and 6th.

CEO Lee said, “SK nexilis is a company specializing in copper foil expansion. As the copper foil market grows and Lotte Chemical newly enters the copper foil market, we will compete as the first mover in the copper foil market.”

By Staff Reporter Ji-woong Kim (jw0316@etnews.com)