Applied manufacturing technology for fiber optic base material, localized focus ring ingot production and equipment

Technological independence on M·P·E for synthetic quartz, successfully localized m

Despite the new government's efforts to drive the semiconductor industry, 'Synthetic Quartz', which is at the core of the semiconductor manufacturing process, has been entirely dependent on imports. It is not an exaggeration to say that major companies such as Japan, the United States, and Germany have monopolized it. In particular, since synthetic quartz is a monopoly item, oppressive sales were common. Buyers were often unable to secure supply despite paying advance payments.

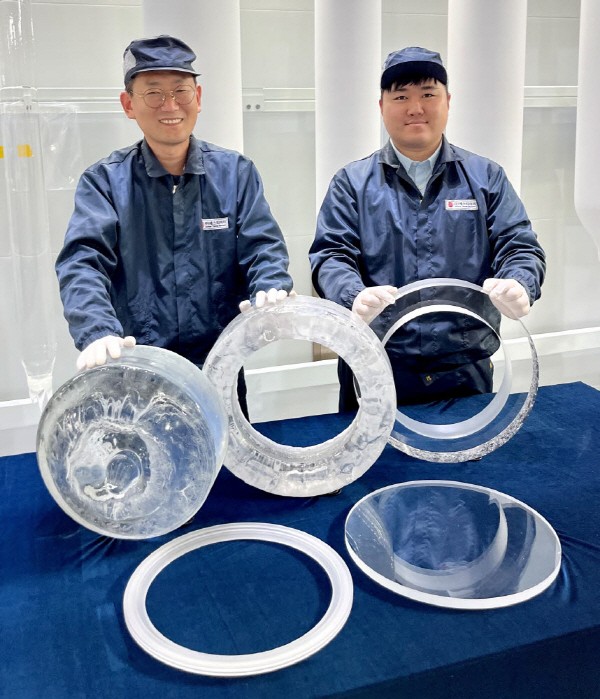

Meanwhile, a Korean company has succeeded in localizing synthetic quartz materials for semiconductor focus rings, using its unrivaled high-purity fiber optic base material manufacturing technology, for the first time in Korea. By independently developing synthetic quartz manufacturing equipment, it has given the green light on the domestic quartz market, which is barren of materials.

The main character is STI (CEO Tae-il Seo), a company specializing in optical fiber base material equipment in Daegu. STI succeeded in localizing synthetic quartz material for the first time in Korea, challenging the global synthetic quartz market beyond Korea.

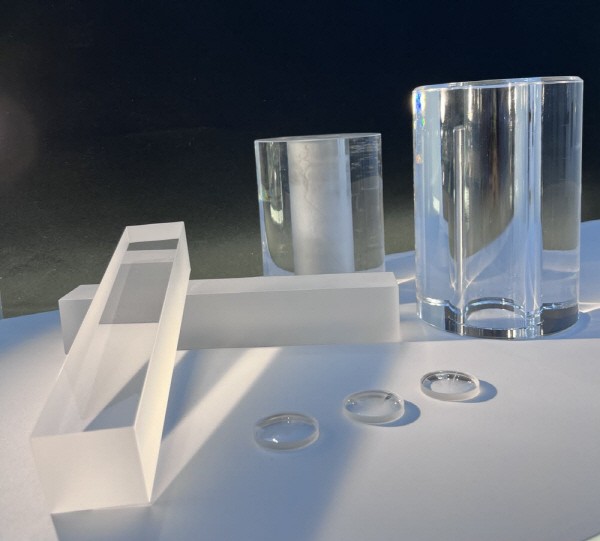

STI cooperated with the Korea Institute of Ceramic Engineering Technology for industry research and succeeded in localizing and mass-producing the synthetic quartz glass material that Japan had monopolized in 2020. Last year, they managed to directly produce synthetic quartz for optics and welding rods, and this time, they developed synthetic quartz materials for semiconductor focus rings.

Synthetic quartz, which is mainly used in the semiconductor etching process, has been imported 100% from overseas such as Japan, the United States, and Germany. Synthetic quartz glass is required for next-generation micro-processing for extreme ultraviolet (EUV) exposure. High-level chemical technology and large-scale facilities are essential, since it requires high purity and high precision. It is a field that requires extensive R&D investments to develop new products every year, in order to respond to improvements in device integration.

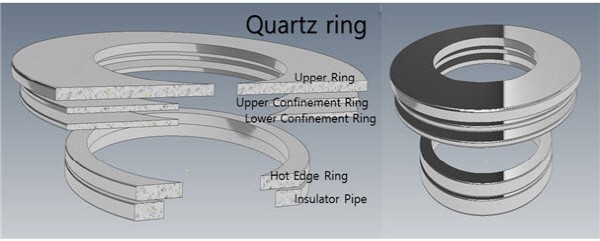

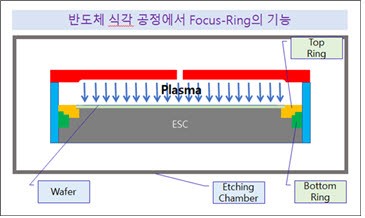

Synthetic quartz material is mainly used in the etching process, so it is typically called the etching process. For semiconductors, it is a process of removing the remaining parts except from the patterns required in the photo process. Like etching engravings, in semiconductors, it is a process of removing the remaining parts except for the necessary patterns from the photo. A circuit is made by leaving the photo resist (IR) formed in the photo process and by removing the remaining part with an etchant (wet) or plasma (dry) method, depending on the etching reaction material. When the etching is complete, the photo resist of the pattern is also removed. With this method, the process of forming hundreds of layers of circuit patterns must be repeated before it can be used as a quartz material focus ring.

Among the etching methods, the method that uses plasma is expensive and complicated. Plasma etching, which can increase yield compared to etchants, is expanding due to changes in semiconductor technology that are highly integrated with units of several nanometers (nm). Using a focus ring made of synthetic quartz material with a long lifespan can improve efficiency. The focus ring is a consumable part that needs periodic replacement because it is easily etched from exposure to the extreme environment of 'High Power Plasma'. This is why steady sales are expected in the future.

Synthetic quartz is a material that has been developed to suit semiconductor production processes. The types of parts include rings, wall liners, wide pockets, boats, plates, baffles, tubes, domes, etc. It is useful for semiconductor etching processes that are integrated below 17nm, due to it having excellent abrasion resistance, light transmittance, and no micro bubbles, so it is useful for semiconductor etching processes that are being integrated down to 17nm. Since synthetic quartz is known to be superior in the semiconductor industry, much of the existing natural quartz is being replaced with synthetic quartz. Experts estimate that the global natural quartz market is currently worth 5 trillion won, and synthetic quartz will replace 30% of this in the future.

In fact, in the case of natural quartz made by melting natural crystals or silica powder (quartz sand) at high temperatures, a certain amount of impurities remain in the raw material no matter how much it is washed. Although quartz glass is a single silica, if the raw material contains impurities, the melting performance changes and the properties become unstable, making it unsuitable for processes due to the high integration of semiconductors.

Accordingly, the synthetic quartz market is expected to continue to grow. As global IT platforms and 5G markets expand and the electric vehicle and autonomous vehicle markets are revitalized, semiconductor manufacturers are investing heavily to keep up with demand.

As the electric vehicle and autonomous vehicle markets are revitalized, investments from semiconductor manufacturers to meet the related demand are continuing.

As the semiconductor parts market averages a compound annual growth rate (GAGR) of 27.2%, the synthetic quartz market is also expected to grow stably. According to a recent survey, the domestic quartz market is estimated to be about 500 billion won based on the sales of quartz materials for domestic semiconductor processes. Among them, Quartz ware for semiconductors accounts for 30-40%.

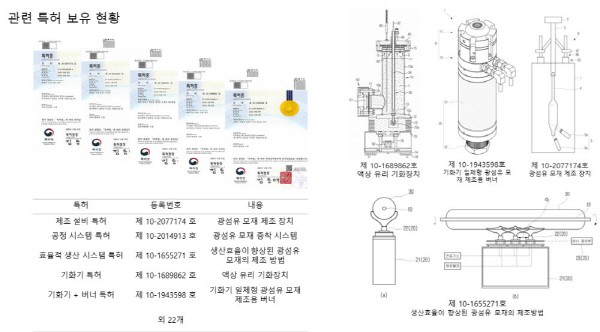

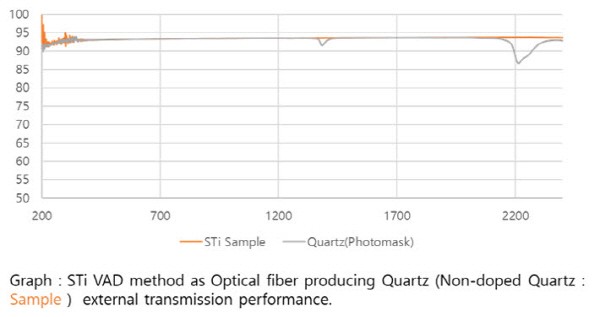

The focus ring synthetic quartz for semiconductors developed by STI is based on the company's high-purity fiber optic base material manufacturing technology. Synthetic quartz manufacturing methods can be divided into the Sol-Gel method, OVD method, and Vapor phase Axial Deposition (VAD) method. The VAD method is a method that implements excellent corrosion resistance and durability due to the low content of hydroxyl groups (OH) and metal impurities that affect resistance. STI manufactures synthetic quartz via the VAD method. In addition, optical fiber manufacturing and base material equipment manufacturing technology are added to meet the requirements for semiconductor materials that undergo high temperature and chemical processes.

STI has purification technology for high-purity silane precursors such as SiCl4 and OMCTS, as well as ingot growth technology via carrier gas control such as high-purity hydrogen (H2), and it even has process control technology to remove OH using high-temperature gas.

Tae-il Seo, CEO of STI, said, “Semiconductor companies are making great efforts to upgrade their technology, but the effects of technology transitions is slowing down," adding, "Unlike in the past, the importance of parts is increasing in order to improve yield or to facilitate technology transitions."

STI believes that the effects of substituting imports will be significant, based on the localization of synthetic quartz materials for semiconductor focus rings. In particular, it is expected that it will be able to respond quickly to the synthetic quartz market, which is experiencing stable growth as demand for semiconductors surges due to the revitalization of the electric vehicle and autonomous vehicle markets. The global market for quartz parts for semiconductors last year was 2 trillion won, and the domestic market for synthetic quartz is expected to reach 150 billion won by 2025.

STI's synthetic quartz production scale is not at a level that can cover all domestic demand. However, supplying material manufacturing equipment and technology, based on the investments of major domestic quartz companies, is expected to have a significant effect on increasing the localization rate of semiconductor technology, by replacing a significant part of the domestic supply of quartz, which has been dependent on foreign countries.

CEO Seo said, “We developed synthetic quartz manufacturing equipment and secured material manufacturing technology in the quartz market, which relied on 100% imports, with the pride that domestic companies would directly manufacture materials," furthermore, “If the supply of quartz is made domestically, away from the oppressive sales of foreign companies, it will help Korea greatly in becoming a semiconductor powerhouse."

Daegu = Reporter Jae-hoon Jung ( jhoon@etnews.com)