Samsung Electronics will independently develop high-purity semiconductor expendable parts used in semiconductor manufacturing with its partners. Reducement of dependence on overseas purchases is expected. It has been understood that Samsung Electronics is developing expandable parts for silicon semiconductors with a number of domestic partners. This is a key expendable part used in the etching process to remove unnecessary sections of the circuit in the semiconductor process. Silicon-based parts and silicon carbide-based products are used in the etching process. Silicon products are necessary in the manufacturing of memory semiconductors such as D RAM and NAND Flash.

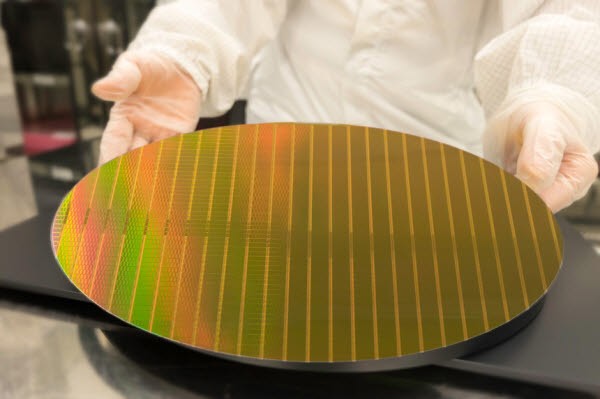

Samsung Electronics is developing silicon expendables with its domestic partners. This includes electrodes that evenly spray plasma when cutting memory wafers, outers that secure the electrodes in place, and focus rings that are used when precisely cutting wafers with plasma.

The reason Samsung Electronics is developing silicon electrodes, outers, and focus rings is to cope with the demand for memory semiconductors. The World Semiconductor Trade Statistics (WSTS) has predicted that the size of the memory semiconductor market will be 182.7 billion USD this year. An increase of 23.8 billion USD from last year's 153.8 billion USD is expected.

Until now, Samsung Electronics has been supplied with etching equipment and most of its etching expendables by global equipment manufacturers. It is interpreted that domestic suppliers have diversified due to increased supply and demand for semiconductors. Domestic electrodes, outers, and focus rings are known to have price competitiveness compared to overseas products.

Samsung Electronics is known to be purchasing products from overseas equipment manufacturers at higher prices than domestic products. It is also known that the proportion of domestic supplies of Samsung Electronics expendables is insignificant.

By Staff Reporter Ji-woong Kim jw0316@etnews.com