Utilizes the existing reflected light and light transmission 'backlight'

Applies 20 years of accumulated technology and special ceramics

Reduces the rate of misjudgment and contributes to productivi

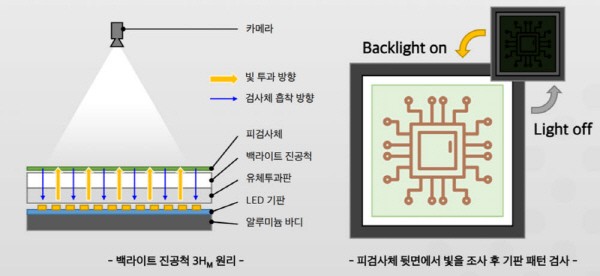

Micropore Co., Ltd. (CEO Jaegu Park), a company specializing in ceramic materials for semiconductors and displays, has developed a ceramic vacuum chuck that allows the transmission of light. When inspecting printed circuit boards (PCBs), the optical inspection efficiency is greatly improved by using 'backlight' that transmits light in addition to the existing reflected light. Micropore is the first company to create an 'end-to-end' solution from ceramic materials to light-transmitting vacuum chucks.

The light transmission efficiency of the Micropore backlight vacuum chuck device is about 10%, which is superior to general display transmission characteristics (6-7%). With the backlight vacuum chuck developed by Micropore, it is possible to fix the inspection object such as a thin and flexible PCB without distortion and to improve the optical inspection performance.

The vacuum chuck is used to fix semiconductor wafers, display panels, and flexible PCB boards during the process. A thin PCB is attached to the ceramic plate with a vacuum chuck, and defects are inspected with an automatic optical inspection system. The most typical task is to determine whether the 'via hole', a hole used to connect circuits on a flexible PCB, is properly drilled.

Existing vacuum chucks could only perform optical inspections using reflected light since the ceramic that holds the PCB and other components in place did not allow light transmission. Because the amount of light required for optical inspection was small, inspection efficiency was lowered. Misjudgment could occur such as non-detection, which concludes that the product is good when it is actually bad, or over-detection, which determines that the product is defective due to foreign substances like dust. Over-detection is a factor that reduces productivity by automatically disposing of good products that have been manufactured with great effort.

Micropore has developed a new material that allows light to pass through the ceramic plate in the vacuum chuck to increase optical inspection efficiency. A special ceramic material that allows light transmission is made with a special ceramic material. By applying a light-emitting diode (LED) to the back of the ceramic plate, the optical inspection performance was improved by using both reflected light and transmitted light. Since sufficient light is available, it is possible to accurately detect patterns or via hole openings in translucent film-type PCBs. This is the result of accumulated technology by developing porous ceramic materials for more than 20 years. In addition to the new ceramic material, Micropore's proprietary technology, such as the 'micro-ceramic flotation unit' that precisely floats the PCB board and adsorbs it to the ceramic plate, was applied to the vacuum chuck equipment. Micropore also applied for a patent related to the backlight ceramic vacuum chuck.

Micropore Co., Ltd., which began as a laboratory startup at Hanyang University 20 years ago, has been well received by revealing its backlight ceramic vacuum chuck equipment at the recently held 'Smart Factory + Automation World (SFAW) 2022'. The company is discussing equipment supply with semiconductor and substrate manufacturing equipment companies.

CEO of Micropore Jaegu Park said, “As the volume and complexity of items to be inspected for product control using images captured with a vision camera (optical inspection) and image processing algorithms increases, so does the rate of false detection, resulting in additional inspection expenses. The backlight ceramic vacuum chuck equipment will contribute to thorough quality control and productivity increase by providing an effective optical inspection."

By Staff Reporter Dongjun Kwon djkwon@etnews.com