Explosive facility investment... bottleneck effect in parts industry

MCU·PLC may take up to 1 year

Disruption in production due to increased raw material prices

Concerns over 'prolonged' semiconduc

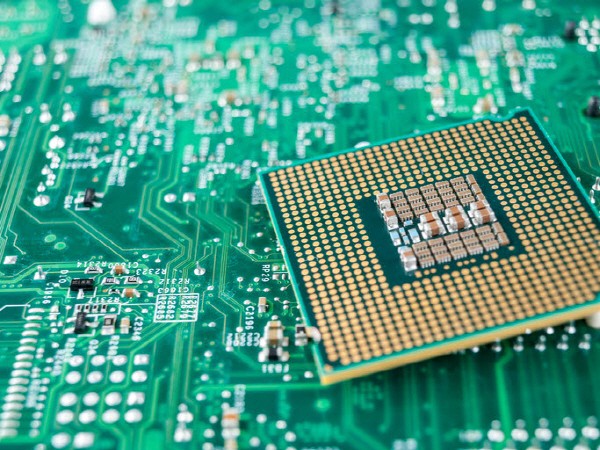

Compared to usual, the delivery period (lead time) of advanced parts required for manufacturing semiconductor was delayed by more than double. The circumstance occurred due to demand for semiconductor equipment has soared, and creating a bottleneck in the supply of parts. A vicious cycle continues in the supply of equipment due to the increased cost of raw materials and the shortage of equipment semiconductors.

The period of delivery of core parts of semiconductors is more than 6 months compared to the usual 2-3 months. The lead time for advanced parts from the United States, Japan, and Germany has increased significantly. Products that are experiencing the bottle neck effects are advanced sensors, precision thermometers, microcontroller units (MCUs) that manage equipment, and power line communication (PLC) devices. Some parts, such as PLC devices, were delayed for more than 12 months.

An official from a semiconductor equipment manufacturer said, “Semiconductor equipment manufacturers that placed an order last year, but did not secure stock experience difficulty producing equipment. The equipment delivery date is being delayed as the parts delivery period is getting longer.”

A test equipment manufacturers that relied on imports from the United States tried to purchase parts locally, but was unable to do so due to a lack of stock at the parts manufacturers. Companies are experiencing difficulties in securing parts and casting parts for semiconductor equipment as the price of raw materials such as aluminum and steel has soared.

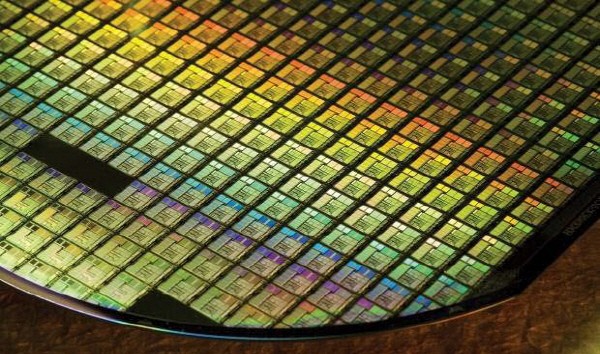

The shortage of parts for semiconductor equipment is due to a surge in demand. Orders for semiconductor equipment have skyrocketed as global semiconductor manufacturers have invested heavily in facilities to solve the semiconductor supply shortage. In some cases, the delivery period of equipment, which used to take several months, exceeds two years. The entire parts inventory was exhausted as the equipment industry quickly increased production in response to the surge in demand. Overseas parts manufacturers have not increased their production capacity significantly, and it is another factor for the shortage. Semiconductor equipment manufacturers responded sensitively to facility investment, and began to rapidly expand production capacity; however, parts manufacturers responded late.

An industry official said, "Semiconductor equipment companies can easily increase their production capacity having a clean room, but many things are required for parts companies to build a new infrastructure. The parts companies carries a heavy burden with large-scale facility investment, and caused the bottleneck.”

Domestic semiconductor equipment manufacturers face another problem with being pushed back in the priority list for the supply. This means that major overseas parts manufacturers will supply to top semiconductor equipment manufacturers such as Applied, ASML, TEL, and Lam Research first. The domestic semiconductor equipment manufacturers with relatively low sales received small number of parts.

The global semiconductor supply shortage is expected to get worse as the production of manufacturing equipment is disrupted, which is a key element in semiconductor production. The duration of equipment investment by semiconductor manufacturers is inevitably slow as the delivery date of semiconductor equipment is delayed due to empty inventory.

Kihyun Ahn, senior executive director of the Korea Semiconductor Industry Association, said, “It is necessary for the semiconductor equipment industry to lead the development of equipment parts ecosystem, just like the domestic semiconductor equipment ecosystem was created through cooperation with semiconductor device companies.”

By Staff Reporter Dongjun Kwon (djkwon@etnews.com)