SK siltron is starting the operation of Silicon carbide (SiC) semiconductor wafer manufacturing plant (fab) constructed in Bay City, Michigan, USA. They will respond to local semiconductor needs from STMicro, Infineon and more. SiC Wafer is core component of next generation power semiconductor. The production capacity of SK siltron’s Bay City fab has not been verified. However, annual production is expected to be around 60,000, which is larger than the existing Auburn fab. SK siltron official said “Bay City wafer fab will be flexible in responding with demands from ultra-low power, automobile semiconductor.”

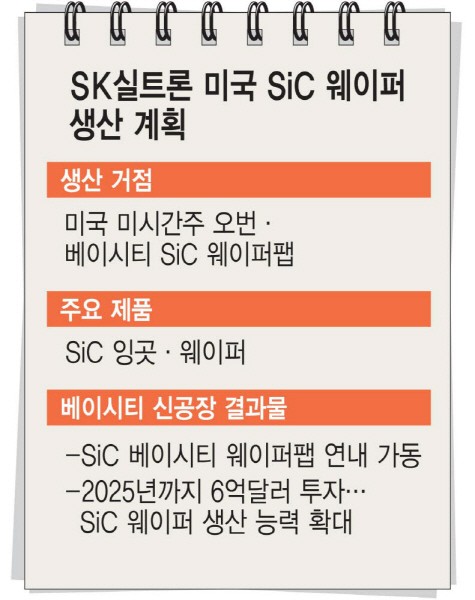

SK siltron is operating 2 wafer fabs in Michigan, USA. In the second half of last year, they purchased the site of another factory in Bay City which is near the Auburn factory and changed its usage to SiC fab. That fab will produce base material of silicon carbide wafer, which are ingot and wafer. 6-inch SiC wafer is their main product. In the future, they plan to produce large scale wafer such as 8-inch SiC wafer.

SK siltron acquired the research organization and manufacturing facility of the Auburn SiC division in the US from DuPont US for $450 million in 2019. It seems that they are putting much efforts for early operation of Bay City fab based on SiC wafer manufacturing technology. With the operation of new Bay City plant, they can respond to demands of SiC semiconductor. They plan to invest $600 million to raise the US SiC wafer production capacity.

Yong-ho Jang, CEO of SK siltron, got on plane for a business trip to the United States this week. It is understood that he got on a business trip to the US to review the planning of semiconductor supply chain, including wafer production schedules at the Bay City plant. SK siltron is currently supplying silicon wafers to Samsung Electronics and SK hynix.

SiC power semiconductor market is expected to grow from 885.66 million dollar in 2021 to 3.398 billion dollar in 2025.

By Staff Reporter Ji-woong Kim <jw0316@etnews.com>