BCNC, which developed the world's first synthetic quartz material and parts for semiconductors, will quadruple its production capacity this year. Their strategy is to secure global semiconductor companies as customers and respond quickly to the rapidly increasing demand for synthetic quartz consumables. They are pioneering a new market with a new material that overcomes the limitations of existing natural quartz parts.

BCNC announced on the 27th that they have recently completed a new synthetic quartz manufacturing plant and they are set to start operations. They have secured a total of four production lines that can manufacture more than 100,000 synthetic quartz focus rings per year. Last year, BCNC's synthetic quartz focus ring production was at 25,000 units, and once they begin operating the plant, they will be able to secure more than four times their production capacity (capa). Currently, they have completed construction of their first line facility and began operations. Their goal is to achieve 90% yield by the third quarter. By the fourth quarter, their entire line will be operational and they will start mass production.

Synthetic quartz has a longer life cycle and fewer particles than conventional natural quartz parts. It is in the spotlight as a new material that will increase the yield of semiconductor processes. BCNC, along with U.S.' Corning Inc. was the first in the industry to develop synthetic quartz and is the exclusive supplier of related materials. They are mainly supplying consumable focus rings that fix wafers in semiconductor etching processes, to semiconductor device companies.

The customer base is growing, as the excellent performance of synthetic quartz becomes more well-known. BCNC has already secured Samsung Electronics and SK Hynix as customers. Considering the amount of contracts completed this year, sales are expected to increase by more than 40% compared to last year. BCNC is also supplying synthetic quartz parts kits to semiconductor equipment companies.

This new plant manufactures focus rings with self-developed synthetic quartz materials. Last year, the company succeeded in localizing new materials, which can shorten the processing time of synthetic quartz and secure competitive prices. Their strategy is to maximize the competitiveness of synthetic quartz products by internalizing materials that were supplied from outside. Analysts say that the new material is eco-friendly because harmful gases such as hydrogen chloride are not generated during the manufacturing process.

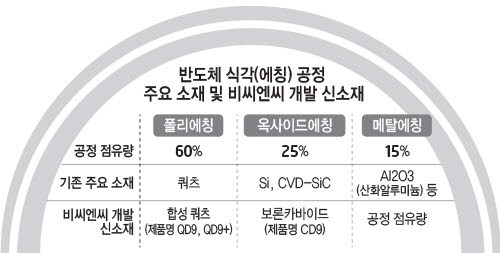

BCNC expects to replace most of the natural quartz market for semiconductors with synthetic quartz. This is because as demand for advanced processes increases, more materials and parts are required to increase yields. According to the BCNC, the global natural quartz market is currently estimated at around 5 trillion won, of which 30% can be replaced by synthetic quartz. In particular, penetration is expected to accelerate in the etching process and plasma utilization process.

BCNC also has its sights set for the oxide etching market. Unlike poly etching which uses quartz, oxide etching parts use silicon or chemical vapor deposition silicon carbide (CVD-SiC) as the main material. BCNC has developed a new boron carbide material with a reduced carbon content compared to CVD-SiC. With smaller carbons, the residue inside the semiconductor process chamber can be minimized, thereby increasing the process yield. The new boron carbide material has completed a yield improvement performance test with its customers and is currently in the stage of verifying its life cycle. Their goal is to mass-produce next year.

"We have completed the vertical integration of materials and parts by developing and localizing new products while replacing the existing natural quartz market," said Don-han Kim, CEO of BCNC. "We will further expand our product portfolio and production capacity to become a global material and parts company."

By staff reporter Dong-jun Kwon (djkwon@etnews.com)