Wet separating membrane company Enerever Battery Solution took over dry separating membrane company, Ecell Tech. It became the first comprehensive separating membrane company to secure wet and dry method. It is confirmed on the 23rd that Enerever Battery Solution acquired Ecell Tech’s assets such as dry separating membrane factory and facility through a corporate auction. Details regarding the contract was not disclosed, but it is known that scale of the contract was about a few billion KRW.

Ecell Tech is a company with dry separating membrane technology. They operate dry separating membrane manufacturing factory in Chunghu, Chungbuk with 8 million ㎡ scale. Although they passed the dry separating membrane quality approval for the large Korean battery company, the operating funds ran out and the company entered the corporate rehabilitation process in 2018. They submitted rehabilitation plan to the court, and through M&A process, they accepted Enerever Battery Solution as their new owner.

Separating membrane is part of 4 key materials of secondary battery. They are position between anode and cathode of secondary battery in order to physically prevent their contact and secure safety. Through micro pores in separating membrane, it allows ion to travel to generate current.

Separating membrane is divided into wet separating membrane and dry separating membrane. The wet type is used for high value-added batteries based on Nickel made by LG Energy Solution, Samsung SDI, and SK on. The dry type is used for low-value batteries based on LFP such as CATL, BYD, and SVOLT.

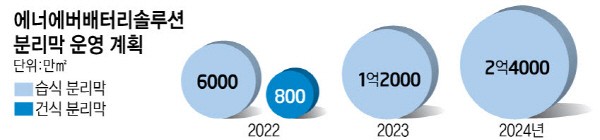

Enerever Battery Solution became the only company in Korea manufacturing both wet and dry separating membrane by taking over Ecell Tech. To align with the growth of EV battery market, the company plans to strengthen competitiveness in price, quality, and localization of facilities. With Ecell Tech's dry separating membrane for energy storage systems (ESS) on LFP batteries, they plan to expand their sales in Asia starting from China. Sanggi Shin, CEO of Enerever Battery Solution, said, "We plan to hire new workers. We are planning to supply wet separating membrane to domestic battery companies and dry separating membrane mainly for ESS."

Enerever Battery Solution is targeting their annual sales up to 20 billion KRW this year, starting with the supply of wet separating membrane. Thy plan to achieve 40 billion KRW in 2023 and 100 billion KRW in 2024. They will also pursue to be listed after 2024.

By Staff Reporter Jiwoong Kim (jw0316@etnews.com)