eveloped 'PGMEA' with purity of 99.999%

Realization of 'the highest level' of Japanese restricted items

Reduce the content of harmful substances to 1ppm

Invest 20 billion KRW to build mass product

Chemtronics has succeeded in developing a core solvent for the extreme ultraviolet (EUV) process for semiconductors, which is highly dependent on foreign countries. It is a raw material necessary for the manufacture of 'photoresist (PR)', one of the items that Japan has restricted for export. They realized it with the highest level of purity in the industry. They also minimized the content of harmful substances to respond to customer environmental, social and governance (ESG) management. Chemtronics will also invest 20 billion KRW in facilities for mass production.

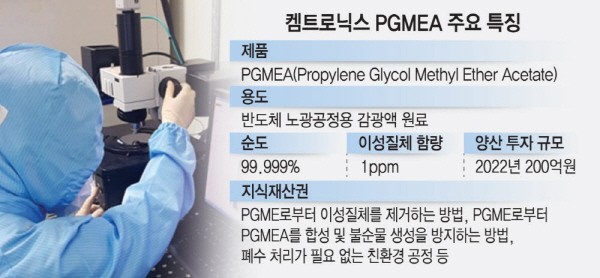

Chemtronics announced on the 7th that they have developed ultra-high purity 'PGMEA', a key solvent for semiconductor and display manufacturing processes. PGMEA is a major solvent that accounts for 70-80% of PR materials used in the semiconductor exposure process. So far, it has been imported from Japan and China.

Chemtronics' localized PGMEA boasts 99.999% (5N) ultra-high purity. Currently, most of the PGMEA applied to PR is 99.994~99.996%, which does not reach perfect 5N. Ultra-high purity solvents are essential for EUV PR development. Chemtronics explains that their PGMEA is advantageous for controlling EUV PR defects which is extremely difficult. Chemtronics expected that the localization of PGMEA would boost the EUV PR development of their customers.

It is also characterized by maximizing eco-friendly elements by minimizing the beta isomer, a substance harmful to the human body. PGMEA currently in the market has a beta isomer content of about 100 to 300 ppm. Chemtronics succeeded in lowering the beta isomer concentration to below 1 ppm to reduce the biotoxicity of PGMEA.

Chemtronics CEO Bo-kyun Kim said, “Global companies have been demanding that the content of beta isomers to be lower than 10 ppm as they are classified as hazardous substances. We succeeded in developing and commercializing eco-friendly PGMEA technology of less than 1ppm for the first time in the world after 3 years of full-scale R&D and facility investment.” Chemtronics is applying for patents on ultra-high purity PGMEA manufacturing method and isomer removal method.

Chemtronics will make a large-scale investment to mass-produce ultra-high purity and eco-friendly PGMEA. They plan to invest 20 billion KRW this year alone to build a mass production line. The company also expanded the PGMEA refining facility in 2020. It is a stepping stone to use PGMEA for semiconductor processing as a new growth engine. Chemtronics expected to significantly improve dependence on imports worth 240 billion KRW in the short term by expanding their PGMEA production capacity.

Chemtronics plans to secure a diverse product portfolio with the technology accumulated through the development of ultra-high purity and eco-friendly PGMEA. They will expand their business base by challenging the localization of raw materials used in the display process as well as semiconductors. Chemtronics said, "As ESG management started in earnest, the development of ultra-high purity materials and the development of hazardous substances control technology will serve as a catalyst to change the perception of eco-friendly materials throughout the industry."

By Staff Reporter Dong-jun Kwon (djkwon@etnews.com)