Daejoo Electronic Materials develops pure silicon, which is attracting attention as a next-generation material. Pure silicon is a next-generation secondary battery material that improves the problem of silicon volume expansion during charging and discharging. Daejoo Electronic Materials is the first in Korea to develop pure silicon that reduces the size of silicon particles to nano-class.

Pure silicon, developed by Daejoo Electronic Materials, is a next-generation silicon anode material that is expected to be installed in electric vehicles along with smartphones. The development of pure silicon by Daejoo Electronic Materials is expected to be applied to electric vehicle along with power tools and smartphones.

Pure silicon is the material Tesla, Porsche, Volkswagen, and Apple are applying to electric vehicles. Tesla and Porsche are reportedly equipped with silicon anode materials in electric vehicles and are pushing for the application of pure silicon to new electric vehicles. Volkswagen and Apple are also interested in silicon anode material technology and are expected to apply pure silicon to their products.

Daejoo Electronic Materials is the only company in Korea that commercialized silicon anode materials. Anode materials with a silicon content of more than 5% developed by the company have been applied to Porsche Taycan. It is drawing attention by improving the volume expansion problem caused by increasing the silicon content with materials and processing technologies.

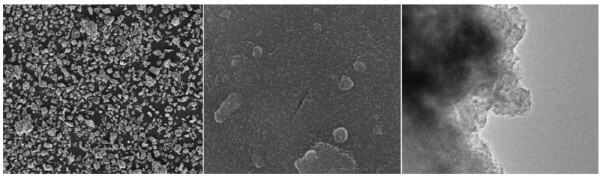

Pure silicon is an improved material than silicon anode material, and the particle size of the anode material is reduced to nano (nm) size. Existing 70-80 nm anode materials have been applied to power tools, but they are attracting attention by reducing the size of pure silicon particles to 2-3 nm. It is known that none of the companies have commercialized pure silicon of this size yet. Daejoo Electronic Materials is promoting development with the aim of applying the materials to electric vehicles as well as power tools and smartphones.

By Staff Reporter Ji-woong Kim (jw0316@etnews.com)