Semiconductor raw materials… 20%↑ than last year

All the prices for materials, parts and equipment rose, price of chip increase is inevitable.

Impact on finished products such as home appliances and

The raw materials price for semiconductors such as wafer rose sharply. As the prices of materials, parts, and equipment all rose, it became inevitable to raise the price of semiconductor chips which would be the final product. It is expected that a domino effect of increasing price for finished products such as semiconductor-based home appliances and automobiles will be continued. As the foundry bottleneck deepens, the semiconductor supply shortage is expected to continue until next year.

According to domestic foundry companies such as Samsung Electronics, DB HiTek, SK Hynix System IC, and Key Foundry, the purchase price of 8-inch semiconductor wafers increased by about 20% compared to the previous year. Some companies are also experiencing difficulties in supply and demand. This is in the aftermath of Shin-Etsu, the world's No. 1 wafer maker, announcing a 20% price increase in April. SK Siltron, the only wafer supplier in Korea, did not immediately raise the price through a long-term contract method, but the price increase is inevitable when the contract is renewed.

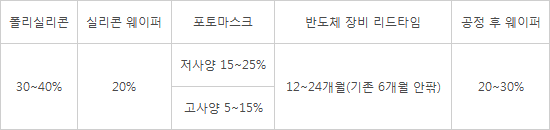

The rise in wafer prices is combination of a surge in semiconductor demand and a rise in the price of polysilicon, a raw material. As China, the world's largest polysilicon producer, adjusted production and it caused rise of domestic polysilicon prices by up to 40%. The price of wafers rose, therefore, rising production costs throughout the entire chip mass production cycle became a reality. As for equipment, the supply period is getting longer due to increased investment in semiconductor factories (fabs) and prices are rising. Used semiconductor equipment prices also rose. The price of a photomask, a key part of the process, also rose by 15-20%, so foundries raised service prices 2-3 times this year alone.

After the process of engraving the semiconductor circuit pattern, the wafer price increased by 20-30%. Post-process wafers are wafers that fabless consigns production to a foundry and then purchases. It is considered to be the biggest factor in the price increase of the final semiconductor chip. As the post-process wafer price rose, fabless recently raised the price by product to around 20%. An official from a fabless company that makes display-related chips said on the 14th, “We negotiated to supply the chips to panel makers by raising the price of the chips due to the foundry price hike. The panel manufacturer also understood the situation and decided to accept the increased price.” Another fabless representative emphasized, "This is the first time that the chip price has been raised in last 10 years."

Semiconductor chip price hikes are expected to continue for some time in line with the surge in demand. Some foundry companies have completed reservations by the first half of next year. It is expected that the situation in which finished products cannot be made because semiconductor chips cannot be obtained until next year. It is predicted that price hikes for finished products such as TVs, mobile phones, and automobiles are only a matter of time.

◆ Price increase of major items in the semiconductor process (compared to the previous year)

industry collected data

By Staff Reporter Dong-jun Kwon (djkwon@etnews.com)