Nepes has started mass production of ‘Fan out-Panel Level Packaging (FO-PLP)', which is called the next-generation packaging technology. The mass-produced product is a power management integrated circuit (PMIC), and this is the first time to mass-produce PMIC packaging using FO-PLP. Nepes will continue to expand its FO-PLP production capacity to preoccupy the next-generation packaging market.

According to the industry on the 4th, Nepes recently started operation of its FO-PLP plant in Cheongan-myeon, Goesan-gun, Chungcheongbuk-do.

It is mass-producing global semiconductor fabless’ PMIC products with FO-PLP. The monthly production capacity is said to be 1,000 sheets based on square panels. It is about 5,000 sheets in terms of circular wafer packaging. Although it is small amount as its initial start, it is attracting attention as the next-generation packaging technology that will be the first to mass produce PMIC with FO-PLP.

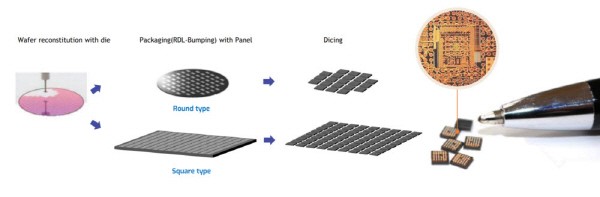

Nepes’ FO-PLP is one of the next-generation packaging technologies. Fan out (FO) is a technology that can increase the number of inputs/outputs (I/O) by placing semiconductor I/O terminals outside the chip. It is advantageous for improving chip electrical performance and thermal efficiency. Panel-level packaging (PLP) is a method that directly connects and packages chips and devices on a rectangular panel. Since it is a rectangle, it is possible to minimize the discarded border compared to the circle. This means that chips can be mass produced. The new technology is evaluated as a technology that is more advanced than wafer level packaging (WLP) with its strengths.

The FO-PLP process introduced by Nepes to the Cheongan plant uses 600mm square panels. About 5 times as many chips (Die) can be produced compared to a single 12-inch (300 mm) circular wafer. From the customer's point of view, it is expected that PMIC will be able to secure high productivity and gain market competitiveness. PLP is evaluated to have 96% higher productivity than WLP method.

Nepes plans to continuously expand its production capacity in response to the growing demand for PMIC. It is said that the production capacity will increase more than triple by the end of the year, and it will secure a monthly panel production capacity of 3,000 panels in the first half of next year. It is about 15,000 sheets per month when converted to circular wafers.

It is known that Nepes is considering an increase in the number of orders from its customers and is also considering expanding additional production lines. An official from Nepes said, “It is difficult to disclose specific details due to a contract with customers.”

As it begin its mass production, Nepes is expected to enter the global FO-PLP market. Although FO-PLP is an advanced packaging technology, the market size is small. Currently, only Nepes, Samsung Electronics, and some Taiwanese packaging companies have FO-PLP technology. According to market research firm Yole Developpement, the FO-PLP market is expected to grow from $18 million in 2018 to $119 million in 2024.

By Staff Reporter Dong-jun Kwon

(djkwon@etnews.com)