1000 times finer measurement than existing products

130 domestic and overseas supply... performance verified

Helps to improve yield by applying many special functions

PS Tec, a company specializing in electrical control devices, has developed an electrostatic chuck (ESC) power supply that can minimize damage to wafers and display substrates by applying special functions. The product has proven its performance by successfully supplying it to domestic and foreign semiconductor equipment companies. Since there are many equipment companies that have completed product testing or are currently in the process of testing, additional supply is expected.

PS Tec announced on the 2nd that it has developed an ESC power supply that can measure capacitance with ultra-fine unit of 'picofarad (pF)'and monitor leakage current in real time, and has delivered 130 units to domestic and foreign semiconductor equipment companies.

In particular, it has been recognized for its product excellence in the global market by supplying it to company A, a global semiconductor equipment company. PS Tec is the first to measure the capacitance in pF units to check various wafer status abnormalities.

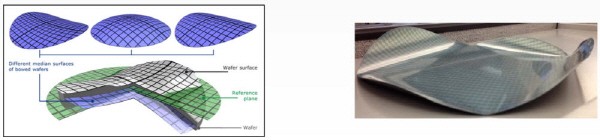

ESC is a key process device that fixes the wafer and display substrate to the lower electrode using electrostatic force by the power supply that generates a voltage to create static electricity at ESC. The ESC power supply device developed by PS Tec can check whether the wafer or display substrate is properly fixed or detached (chucked/de-chucked) on the ESC through capacitance measurement.

There were existing ESC power supplies that measure capacitance in nanofarads (nF), but there were many voices demanding more precise measurement performance because the measurement value deviation was not significant. In response to the needs of semiconductor equipment makers, PS Tec explained that they have developed a device that detects abnormalities in wafers or display substrates in advance by checking changes in capacitance up to pF units, which is a very ultra-fine unit. pF can yield measurements that are 1,000 times finer than nF.

The product can also monitor leakage current in real time. Leakage current may occur due to damages inside the ESC during the process, which adversely affects the fixing of wafers or display substrates, resulting in a decrease in yield. The PS Tec ESC power supply is equipped with a function to check the leakage current in nanoampere (nA) units and warn when the limit value is exceeded. It also supports fast wafer detachment and can increase the efficiency of the manufacturing process. A company official emphasized, "We applied a lot of special functions that can identify abnormal ESC status, such as checking whether the voltage inside the ESC is fluctuating."

PS Tec is preparing for additional supply to semiconductor and display equipment companies by setting up a product mass production system this year. Excluding customers that have already been supplied, product tests have been completed or are in progress with 3 semiconductor equipment and 5 display equipment customers.

PS Tec CEO Hwan-ho Sung said, “We plan to actively target the ESC power supply market, which is highly dependent on foreign products with differentiated functions. We will prove that semiconductor and display yield improvement and quality improvement are possible through the new ESC power supply.”

By Staff Reporter Dong-jun Kwon (djkwon@etnews.com)