Samsung D developing evaporator with ULVAC Japan

LGD cooperates with domestic Sunic System

Increased substrate size to improve production efficiency

Responding to demand for smartphones, laptops, and

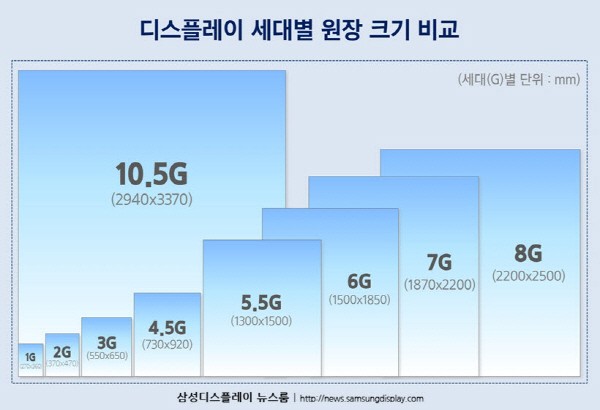

The small and medium sized organic light emitting diode (OLED) display industry has entered an inflection point. Major display companies such as Samsung and LG are converting their small and medium sized OLED panel manufacturing technology, which has remained in the 6th generation, to the 8th generation. In the display industry, a generation is the size of a glass substrate. The higher the generation, the larger the substrate size, which means that larger displays can be produced more efficiently. In an attempt to expand small and medium sized OLED applications from smartphones to tablets and laptops, investment plans seem to be visible within this year.

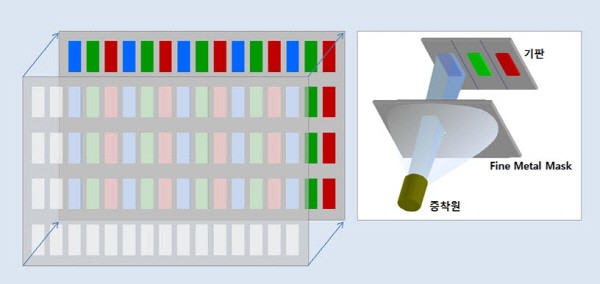

It is understood that Samsung Display and LG Display are developing 8th-generation evaporator. The evaporator is a key equipment that forms red (R), green (G), and blue (B) pixels. Like water vapor condensing on the lid when boiling water in a pot, the OLED material is heated and settled on the substrate. Samsung Display is developing an 8th generation evaporator with Japan's ULVAC, while LG Display is developing it with Sunic System in Korea. Japan's DNP is also known to have started developing the 8th generation FMM (Fine Metal Mask). FMM is a thin metal plate with small fine holes, which induces the OLED material to be deposited in the required position on the substrate. OLED displays express images with organic materials that emit light on their own, so material deposition is very important. This is why evaporators and FMMs are considered as key equipment and materials for OLED panel manufacturing.

Samsung Display is the No. 1 company in the small and medium sized OLED market. DNP is a company that exclusively supplies FMM to Samsung Display. LG Display is also a major manufacturer in the small and medium sized OLED market. It is analyzed that the 8th generation OLED conversion and panel commercialization of companies leading the global small and medium sized OLED industry is now within the visible range. An official from a display equipment maker explained on the 16th, “The evaporator and FMM are the basics among the basics in OLED panel production. The development of these equipment and materials means that the 8th generation OLED era has come.”

The background of this conversion would be the expansion of the small and medium sized OLED market. In the meantime, small and medium sized OLEDs have grown centered on smartphones. The industry grew as OLED replaced smartphone screens that were dominated by liquid crystal displays (LCDs). However, as the smartphone market became increasingly saturated, sales peaked in 2017, and the penetration rate of OLED in the smartphone market also increased.

Display makers are aiming for tablets and laptops as their next target. LCD screens are still the main focus of these products, and the size is in the range of 10 to 17 inches, so it creates larger market than smartphones. Mass production and price are an issue. OLED is superior to LCD in terms of color reproduction, response speed, and design, but its disadvantage is that it is expensive. In order to mass supply at a competitive price, it is necessary to switch to the 8th generation. The size of the 8th generation glass substrate is 2200 mm in width and 2500 mm in length. The 6th generation is 1500mm and 1850mm. The larger the plate, the more panels can be made at a time, and the production time can be shortened, reducing costs.

8th generation OLED panel mass production is expected to be in 2023~2024. It is analyzed that the development of equipment and materials necessary for manufacturing 8th generation OLED will be completed by next year and mass production will begin in 2023. Investment plans are also expected to be established at the end of this year. Ki-hyun Kim, Director of Stone Partners, said, “There is a possibility of establishing an investment plan for 8th generation OLED at the end of this year. The 8th generation OLED conversion will accelerate the shrinkage of the LCD market and the expansion of the OLED market with the goal of applying information technology (IT) products such as laptops, monitors, and tablets.”

By Staff Reporter Gun-il Yun (benyun@etnews.com)