Samsung Electronicsplans to diversify the supply and demand of Photoresist (PR), a key material for Extreme Ultraviolet (EUV) exposure processes and apply the EUV PR of Inpria, a U.S. semiconductor material company, soon.

Inpria is the only company in the world that makes inorganic based EUV PR, which is evaluated highly for its excellent performance in realizing ultra-fine semiconductor circuits. It is expected that Samsungwill strengthen its EUV process competitiveness and diversify the EUV PR procurement, which has been dependent on Japan.

According to the semiconductor industry on the 26th, Samsung Electronics plans to introduce Inpria's EUV PR into the system semiconductor line within this year. Although the application target has not been confirmed, Inpria’sPR material has advantages in ultra-fine processes and thus it is expected to be used in the latest foundry processes such as 5 nanometers (nm).

Inpria is known to be preparing various infrastructures in Korea, including EUV PR storage facilities, to supply the EUV PR to Samsung.

An industry official well aware of this issue said, "Inpria is preparing to bring EUV PR produced in the U.S. to Korea and supply it to Samsung Electronics' fabs, according to its local supply requirements.”

Another semiconductor company official said, "It is to my knowledge that Samsung Electronics plans to use Inpria’s PR for mass production of system semiconductors."

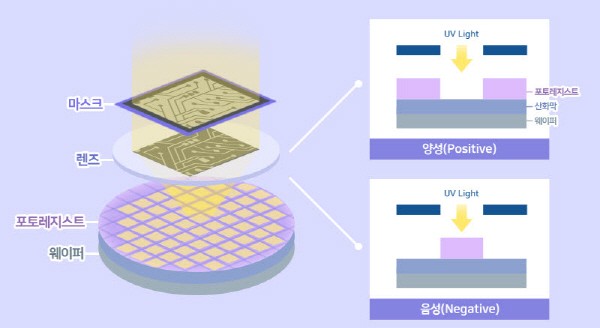

PR is an essential material applied on wafers to make semiconductor circuits. Specialized in the EUV exposure process, Inpria has a PR technology of unparalleled performance. Unlike conventional PRs composed of organic materials, EUV helps form a denser and clearer circuit pattern than before by making inorganic-based PRs with a molecular size of about 1/5th. Paying attention to the PR as a key material for ultra-fine semiconductor process in the EUV era, global semiconductor companies such as Samsung Electronics, TSMC, Intel, SK Hynix, and Applied Materials have all invested in Inpria and supported its commercialization.

Samsung Electronics has completed the performance evaluation of Inpria PR and is pushing for full-scale application as well.

Inpria attended 'Tech Week 2020 Live' hosted by etnews in last September and has equipped itself with the ability to produce more than 4,000 gallons of PR per year at its Oregon plant in the U.S. The industry reported that Inpria EUV PR is used by TSMC and will be expanding to Samsung Electronics.

Samsung Electronics' application of Inpria EUV PR implies that it will strengthenthe ultrafine foundry process. Semiconductor is more difficult to manufacture as the circuit line width becomes narrower, or as it becomes miniaturized. The complexity of circuit is likely to lead to defects, which can lead to deterioration of semiconductor performance and productivity. As Inpria EUV PR can strongly realize ultra-fine circuits and significantly improve unintentional defects during EUV processes, Samsung Electronics is expected to strengthen ultra-fine semiconductor processes, especially foundry process that currently uses EUV the most.

In particular, it is noteworthy that the introduction of Inpria products will diversify Samsung's EUV PR supply and demand. Samsung Electronics is using PRs from Japanese companies such as JSR, Shin-Etsu, and TOK for the EUV process. It has imported PR from Belgium since Japan's export control in 2019, but through a joint venture between JSR and IMEC. U.S.DuPont, which announced an EUV PR plant investment in Korea, has not yet entered the supply chain.

Accordingly, Samsung’s introduction of Inpria PR heralds a change in the EUV PR supply and demand, which was centered on Japan, and is expected to have a significant impact on the industry. Inorganic PR is effective not only for system semiconductors but also for EUV processes for memory, so its use is expected to expand in the future.

Regarding the application of Inpria EUV PR, Samsung Electronics said, "We cannot confirm the contents related to the material supplier."

By Staff Reporter Gun-il Yun benyun@etnews.com