3 K-battery companies' super-gap strategy

LG Energy Solution "to increase cost competitiveness"

Samsung SDI" first mass production of all-solid battery"

SK Innovation "to secure fire safety"

LG Energy Solution, Samsung SDI, and SK Innovation are to lead the future market with EV batteries that have enhanced battery performance and safety. Samsung SDI will start mass production of all-solid-state batteries, whileLG Energy Solutions will set outthe production of lithium sulfur and all-solid-state batteries. SK Innovation, which is leading the market with pouch batteries, is reinforcing the internalization of electric vehicle battery separators. With such a 'technological super-gap', K-Battery will lead the EV battery market.

At the 'Inter Battery 2021' conference, LG Energy Solutionand Samsung SDI announced their next-generation all-solid-state battery technology strategies.

Targeting the high-nickel NCA (nickel, cobalt, aluminum) battery market by supplying prismatic EV batteries to BMW and Volkswagen, Samsung SDIannounced its plans to pioneer the next-generation electric vehicle market with its sulfide-based all-solid-state battery technology.

Heok Jang, Director of Samsung SDI R&D Center, said, “SONY Japan was the first to develop lithium-ion batteries, but now we should be the first to commercialize all-solid-state batteries.With the goal of commercializing sulfide-based all-solid-state battery in 2027, we will prepare ourselves thoroughly to finish the mass production test by 2025."

Samsung SDI stands at the forefront of the mass production of sulfide-based all-solid-state batteries. Among polymer- and oxide-based all-solid-state batteries, sulfide-based all-solid-state batteries are regarded as having the highest ionic conductivity. All-solid batteries improved safety by converting liquid electrolytes into solids, but they are considered to have low ionic conduction. Samsung SDI is not only internalizing solid electrolytes but is also strengthening cooperation with small domesticbusinesses. Jeongkwan , CIS, and ILJIN Materials are conducting mass-production demonstration tests after establishing pilot facilities to mass-produce sulfide-based solid electrolytes and. Determined to compete against TOYOTA, Samsung SDI plans to focus on the development of sulfide-based all-solid-state batteries and realize commercialization ahead of Japan.

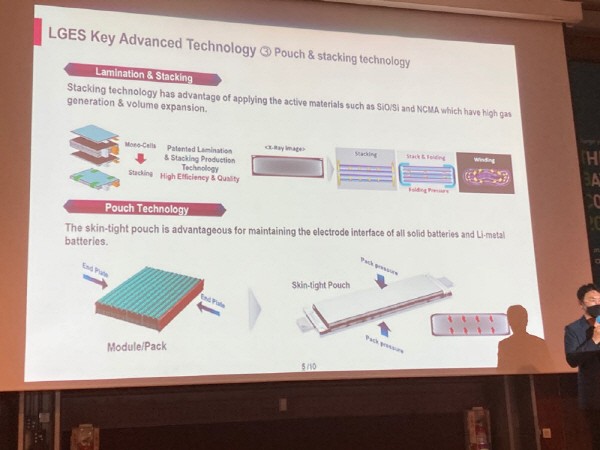

LG Energy Solution is spurring the development of lithium-sulfur battery as well as sulfide-based and polymer-based all-solid-state battery technology. By focusing on high-nickel battery technology with the highest performance in the industry, LG Energy Solution is expected to strengthen the cost competitiveness of all-solid-state and sulfide-based batteries.

“Lithium-sulfur batteries and all-solid-state batteries are attracting attention as next-generation EV batteries due to safety, but there is still a long way to reach commercialization and mass production.” said Je-young Kim, Director of LG Energy Solution Cell Linear Development Center. Among them, LG Energy Solution is paying attention to lithium-sulfur batteries because they have high energy density per weight and sulfur raw materials are cheap to manufacture. Having confirmed the possibility of low-cost and high energy density lithium-sulfur batteries, the company is strengthening its R&D and are putting efforts to lower the battery manufacturing cost. Director Kim emphasized, “We are reducing the cost of raw materials by signing long-term contracts for battery materials to guarantee stable quantities and designing with low-cost structures in materials, processes, and smart factories.”

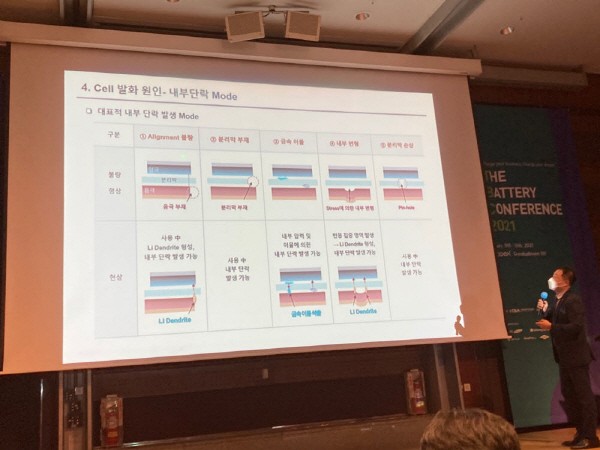

Although a latecomer,SK Innovation is evaluated as the most advanced in the pouch battery market. From this year, the company plans to supply the first batch of NCM (nickel, cobalt, and manganese) batteries. Ford, the second-largest electric vehicle maker in the U.S., has chosenSK Innovation as its next-generation battery supplier. Ford F-150 will be available in three models. SK is strengthening its battery technology from 80% to 90% nickel batteries. While pouch batteries have the highest battery density, its safety issues are emerging.

In response, SK innovation is supplementing the safety of high-nickel batteries with a separator of its subsidiarySK IE Technology. The separator prevents the risk of fire in the high-nickel electric vehicle battery. By freely controlling the thickness of separator and securing micropores, SK is enhancing the performance such as battery energy density. SK Innovation is also strengthening the development of all-solid-state battery technology based on high-nickel battery.

It has been analyzed that SK Innovation is showing prominence in the electric vehicle battery market by expanding its supply to FORDandHyundaiand establishing joint ventures. “SK Innovation will lead the future battery market, by adding new thermal diffusion safety technology to the unrivaled safety technology it has already secured,” said Jon-ha Lee, the Head of SK Innovation Center.

By Staff Reporter Ji-woong Kim ( jw0316@etnews.com)