“Attachable needle” and “smart robotic prosthetic leg” were chosen as this year’s top ten machine technologies.

Korea Institute of Machinery and Materials (KIMM, President Park Sang-jin) announced on Wednesday that “painless attachable needle-nano micro DNA needle patch” technology developed by Jung Joon-ho, who is the head of the KIMM’s Strategy Adjustment division, and “angle-type robotic prosthetic leg technology for assisting lower-limb amputees with normal walking” developed by Woo Hyeon-soo, who is the head of the KIMM’s Medical Support Robot Research division, were selected as this year’s top ten machine technologies by the Korea Federation of Mechanical Technology Societies.

Top ten machine technologies are seen as the corresponding year’s most outstanding machine technologies after they are evaluated by the federation.

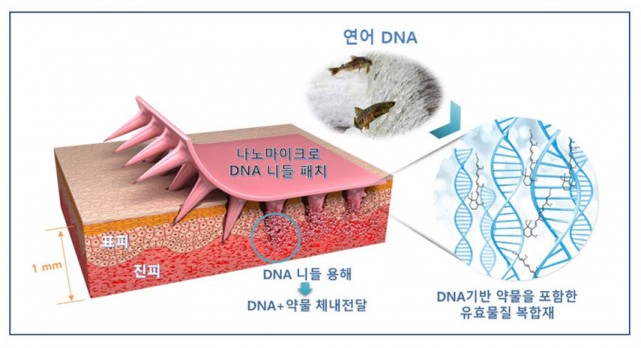

Nano micro DNA needle patch attaches DNA needles that are made through 3D nanopatterning technique onto the skin and inject active ingredients such as vaccine into the skin without pain. This technology is the first of its kind in the world. Based on patents applied in seven different countries including South Korea, the United States, China, and India, the institute has also succeeded in commercialization.

“We will do our best to commercialize the needle patch that is included with vaccines for the flu and new epidemic viruses.” said Jung Joon-ho.

Ankle-type robotic prosthetic leg to assist lower-limb amputee with normal walking is an electronically controlled prosthetic leg that is applied with world’s-best lightweight high-power operation mechanism. Lower-limb amputees can use the prosthetic leg and is able to walk on the ground and go upstairs naturally.

Tests to improve the prosthetic leg’s usability are being conducted with a help from the Ministry of Science and ICT and the Ministry of Veterans Affairs. The robotic prosthetic leg is drawing interests as the institute is planning on a pilot project for people of national merit by the end of this year.

“The robotic prosthetic leg that we have developed only costs one-fourth of foreign products and still has same performance as that of foreign products.” said Woo Hyeon-soo. “We will do our best to go global by diversifying products and securing competitive edge in our products.”

Staff Reporter Kim, Youngjoon | kyj85@etnews.com