To resolve the supply shortage of semiconductors for automobiles and home appliances

DB Hitech and Key Foundry to add facilities

To make use of processing optimization strategy

'Historical performanc

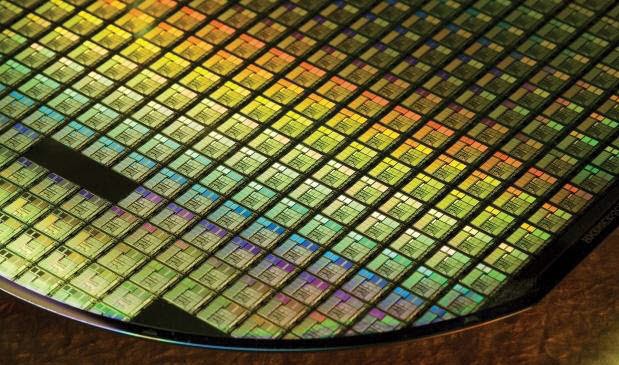

Domestic 8-inch foundry companies have set out to actively expand their production capacity, trying all-out warfare to respond to the surge in demand for semiconductors. Attention is paid to whether this will alleviate the shortage of 8-in wafer-based semiconductors applied to automobiles and home appliances can be alleviated even a little.

According to the industry on the 3rd, production capacity of domestic 8-inch foundries is expected to increase by 20,000 sheets (monthly production capacity of 8-inch wafers) by the end of the year.

DB HiTek plans to increase production to 9,000 sheets this year. It is reported to have achieved 90% of the target already, preemptively responding to the market as demand for 8-inch semiconductors surged. DB HiTek plans to expand its production capacity next year as well by producing more than 10,000 additional sheets per month to secure the production capacity of up to 15,000 sheets. This capacity expansion has increased by more than 10% compared to the previous year It is noteworthy that DB HiTek, which has maintained a conservative investment, will continue to expand production.

Key Foundry will secure an additional production capacity of 10,000 sheets per month by the end of the year. Currently, it has a key foundry production capacity of about 82,000 pieces and plans to have a production capacity of 92,000 sheets by early next year. This means that the company will increase production capacity by more than 10% by the end of the year by purchasing additional equipment such as semiconductor equipment. Launched independently from MagnaChip in September last year, Key Foundry appears to be investing in facilities in earnest.

The CEO of a semiconductor equipment company said, “The supply of semiconductor equipment to key foundries is steadily increasing. We have set out to expand facilities to continuously increase production capacity.”

The strategies adopted by the firms are to purchase new semiconductor equipment and optimize the process, by purchasing and arranging semiconductor equipment necessary for idle space and by changing the process line and work order according to the customer's quantity. This is implied as a strategy to reduce the risk of new line expansion, which requires trillions of investments and two years of time, and to respond flexibly to market conditions.

An official from the foundry industry said “Each fabless uses different equipment and the production periods vary. By analyzing this data and optimizing the process, we can increase our monthly output significantly.”

Strengthening the production capacity of 8-inch foundry companies is an attempt to minimize the semiconductor supply bottleneck. Recently, the demand for semiconductors produced from 8-inch wafers such as power management IC(PMIC), display driving IC (DDI), and microcontroller unit (MCU) has increased rapidly, worsening the supply shortage. Foundry prices also jumped 10-20% in the first half of this year, aggravating the difficulties for semiconductor design firms (fabless). Stronger production is interpreted as a measure to respond to short-term demand.

A semiconductor company official pointed out, “Currently, the 8-inch foundry’s utilization rate is at 100%. We cannot respond to market demand without expanding our production capacity to secure an operating rate of 110-120%.”Such expansion of production capacity by companies is expected to affect the profit improvement of foundry companies, recording unprecedented results thanks to a rise in foundry prices and an increase in production. Jae-yoon Lee, a researcher at Yuanta Securities, predicted that DB HiTek's operating profit in the 3rd quarter would reach 100 billion won for the first time since its foundation. He predicted, “The effect of increased capacity to respond to the severe supply shortage of 8-inch foundries will be reflected in earnings from the third quarter.”

However, the industry agrees that it will be difficult to expand production capacity to the extent that will solve the semiconductor supply shortage. The total production capacity of domestic foundry companies is more than 600,000 sheets per month. 20,000 sheets, which will be meet by the end of the year, is insufficient to meet long-term market demand.

By Staff Reporter Dong-jun Kwon djkwon@etnews.com