Japanese Government directly targeted South Korea’s semiconductor and display industries when it implemented its regulation on exportation of key semiconductor materials on the 1st of July. To retaliate to a decision made by Supreme Court of South Korea on forced labor during the Japanese occupation, Japanese Government decided to pressure South Korean Government and major industries in South Korea by regulating exportation of key semiconductor and display materials. However, South Korean semiconductor and display companies such as Samsung Electronics and SK Hynix have shown to overcome this issue without any setback to their productions after struggling for the past 100 days. Japanese Government’s regulation has actually provided an opportunity for South Korea’s semiconductor industry to improve its makeup and to secure technologies that have distanced South Korea’s semiconductor industry further from other countries.

◊Samsung Electronics and SK Hynix put in huge efforts to overcome Japanese Government’s regulation

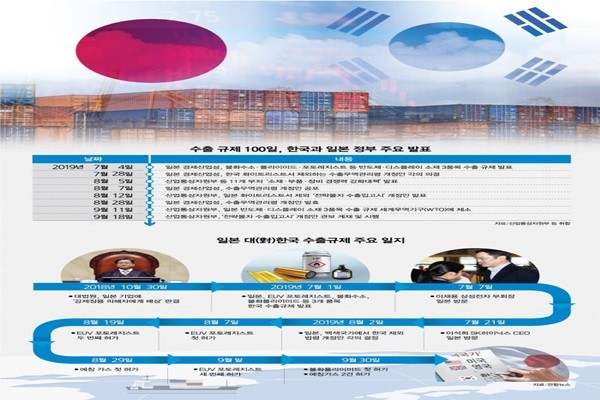

Japanese Government implemented individual approval system to exportation of hydrogen fluoride, EUV (Extreme Ultraviolet) photoresist, and fluorinated polyimide to South Korea on the 4th of July. As a result, each exportation of any of these three materials needs to be approved by Japanese Government.

When Japanese Government implemented this regulation, South Korean semiconductor and display industries were put on emergency alert as they were concerned about having to stop importing these materials and even shutting down their factories.

Experts were also concerned that entire semiconductor manufacturing process in South Korea would be stopped completely because Japanese companies basically monopolize hydrogen fluoride and EUV photoresist that are essential materials for semiconductor manufacturing process.

Fluorinated polyimide, which is a key material for OLED, is also supplied by Sumitomo Chemical. Although the amount of fluorinated polyimide used is relatively low, some thought that it could impact Samsung Electronics’ production of foldable Smartphones.

To prevent semiconductor plants that must be operated 24 hours a day from shutting down due to a conflict between two countries, executives and employees from Samsung Electronics and SK Hynix have put in all of their efforts for the past 100 days.

They have mostly focused on saving whatever is left in their inventories while looking for alternatives. It is heard that they were able to find time to look for alternatives while adjusting production process by either using minimum required amount of a material or reusing a product that had been already used.

Meanwhile, they sent their purchase teams to all over the world and found other suppliers and indirect routes. Vice-Chairman Lee Jae-yong of Samsung Electronics personally visited Japan and looked for a countermeasure. President Lee Seok-hee of SK Hynix also visited Japanese companies and did everything he can to prepare a countermeasure. They have also run their countermeasures that had been prepared since the end of last year by predicting that Japanese Government would regulate exportation of key materials.

As a result, they have been able to come up with alternatives one after the other. They received EUV photoresist, which is the material that is depended the highest on Japanese companies, from RMQC, which is a joint corporation established by JSR from Japan and IMEC from Belgium, to fill any shortage.

They also found alternatives to hydrogen fluoride. Samsung Electronics has been working with SOULBRAIN and ENF Technology since the middle of August and it has started to introduce hydrogen fluoride that is imported from China and Taiwan to part of its manufacturing process. SK Hynix also joined hands with a South Korean company called RAM Technology and it has started to introduce RAM Technology’s hydrogen fluoride to its manufacturing process. LG Display announced that it would only use hydrogen fluoride from South Korean companies for its manufacturing process.

Samsung Electronics and SK Hynix have also dealt with fluorinated polyimide by utilizing their inventories. Also, KOLON Industry, SKC, and SK Innovation finished developing their own fluorinated polyimide and are planning to supply fluorinated polyimide to Samsung Display and LG Display by end of this year.

“It seems that Samsung Electronics and SK Hynix have almost prepared alternatives to three key semiconductor materials.” said a representative for a company. “It is understood that the impact from Japanese Government’s regulation is not as high as initially.”

◊South Korean semiconductor industry starts to diversify sources for semiconductor materials

As uncertainty grows due to prolonged conflict between South Korea and Japan, new dynamics are starting to take placed within South Korea’s semiconductor material industry.

First, semiconductor companies are beginning to diversify suppliers. For example, it is heard that Samsung Electronics finished complete enumeration on parts and materials that had been depended on Japanese companies and has started establishing a BCP (Business Continuity Planning). It is rapidly diversifying suppliers of hydrogen fluoride and EUV photoresist that had been its ‘Achilles heel’ due to high dependence on Japanese companies.

South Korea’s hydrogen fluoride industry is rapidly working on localizing hydrogen fluoride through collaboration between semiconductor device companies and semiconductor material companies. SOULBRAIN is planning to finish the construction of its second plant this month and supply liquefied hydrogen fluoride to Samsung Electronics and SK Hynix. It is heard that the prototype will be supplied to both Samsung Electronics and SK Hynix sometime during this month and the actual product will be used on full-scale staring from the end of November.

“Although it is difficult for us to provide accurate production capacity of our second plant as of now, it will be able to fill any shortage from both Samsung Electronics and SK Hynix.” said Vice-President Park Young-soo of SOULBRAIN.

SK Materials is also planning to finish the development of gaseous hydrogen fluoride by end of this year and start mass-producing it on full-scale and supply it in 2020.

It is heard that Dupont, which had been passive about EUV photoresist market, has been sending its sample to Samsung Electronics and is looking to enter South Korean market.

Japanese companies have not been loosening up as Samsung Electronics and SK Hynix are actively making moves and its competitors are starting to enter their markets that they have dominated.

Because Japanese companies’ customers that are the leaders in memory semiconductor and foundry technologies are located in South Korea, they are significantly important for Japanese companies. If South Korean companies start to diversify suppliers of EUV photoresist especially, Japanese companies will suffer a huge blow to their sales from ArF (Argon Fluoride) photoresist that is commonly used.

As a result, Japanese EUV photoresist supplier called TOK is looking to constructing its production plant in South Korea. It is heard that there is also a Japanese company that is looking into producing photoresists in South Korea and performing quality assurance and R&D at its headquarters in Japan.

“We heard that Japanese companies told South Korean semiconductor device companies about issues that are putting them in a critical situation.” said a representative for the industry. “Japanese companies will be greatly threatened if their path to South Korean markets where many of their major customers are located is blocked.”

Staff Reporter Kang, Hyeryung | kang@etnews.com & Staff Reporter Yun, Geonil | benyun@etnews.com