Pushing ahead with supply to three domestic battery companies

Additional investment of 50 billion KRW in Jecheon Plant

Production target of 3,600 tons per year by 2026

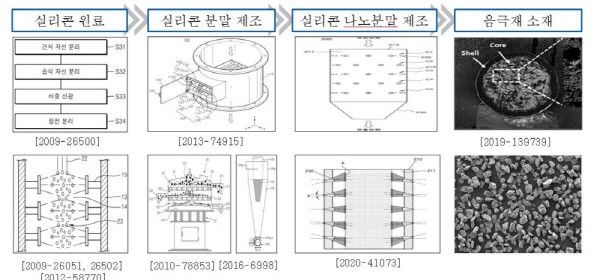

Korea Metal Silicon (KMS) started the commercialization of 100% 'pure silicon' anode active materials. Anode active material is a key material which makes the anode of a secondary battery. It is made only with silicon and is called 'Pure Silicon'. Pure silicon is a technology that is attracting attention as a next-generation anode material.

On the 25th, Jong-oh Choi, CEO of KMS, said, “We have developed pure silicon technology over the past two years with large domestic battery companies and conductive materials companies. Last year, we developed pure silicon anode active material that has level of commercialization and plan to test it by applying it to a battery prototype this year.”

KMS is a basic materials company established in 2008. They supplied metal silicon powder to SK materials, OCI, DONG YANG CHEMICAL from Japan, and Kinsei Matec. Metal silicon powder is used to manufacture polysilicon, a material for semiconductor wafers and solar cells.

KMS jumped into the development of silicon powder based on silicon manufacturing technology. They paid attention to the secondary battery market and invested 10 billion KRW in research personnel. The silicon anode active material developed by KMS was found to have excellent charging capacity.

CEO Choi introduced, "We have achieved a charging capacity of 3650 milliampere hours (mAh, initial efficiency 90%) per gram (g), which is more than 10 times of the existing graphite anode material (360mAh)."

The company explained that they were able to maximize silicon performance by reducing the size of the active material to less than a few nanometers, and improved the structural disadvantage of silicon particles expanding.

CEO Choi said, “KMS plans to process and supply silicon powder to three domestic battery companies for EV batteries, from nano-level silicon to micro-level silicon, which is a raw material for anode materials. KMS powder is used as a basic material for anode materials by domestic battery manufacturers.”

Currently, graphite is used as the main material for secondary battery anode materials. Although it is a stable material, resources are limited and silicon can store 10 times more energy than graphite, so attempts are being made to replace it with silicon. However, since silicon contains more lithium ions than graphite, its disadvantage is that the volume can get expand easily. Accordingly, even when silicon was used as an anode material, its proportion was very a small amount.

KMS' goal is to make and supply 100% silicon anode active materials. The Jecheon plant, which will be completed next month, plans to produce silicon anode active materials. They are planning to invest an additional 50 billion KRW to the Jecheon plant by 2026 to have an annual production capacity of 3,600 tons, including semiconductor and battery materials. The initial production scale of silicon active material was planned at 300 tons.

Silicon anode active materials are scheduled to be supplied to large domestic battery companies that have been developing them together. They plan to supply to Japanese battery makers as well. Starting with Tesla, General Motors (GM), Ford, and Hyundai Motors are expected to install it in their EV.

KMS plans to grow into a representative silicon anode material company in Korea. They are planning to nurture businesses ranging from active materials to anode materials by forming a consortium with copper foil, conductive material, and binder companies that go into anode.

By Reporter Ji-woong Kim <jw0316@etnews.com>