Implemented on a single epitaxial wafer

Reducing the transfer process by one-third

Reducing costs and increasing productivity

Targeting the promotion of commercialization the TV/XR market

A technology that can dramatically increase the utilization and productivity of micro light emitting diode (LED) has been developed in Korea. It is gaining much attention on whether the popularization of micro-LED will be accelerated, which has been making slow progress due to technical difficulties.

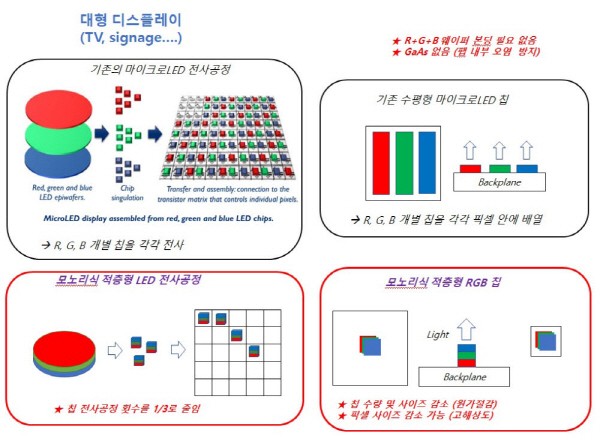

Lumens announced on the 24th that they have developed a Monolithic red, green and blue (RGB) epitaxial wafer for micro-LED. Epitaxial wafer is a substrate which has a light emitting layer, and Lumens’ technology is characterized by stacking RGB on a single wafer.

LED is usually used by connecting electrodes to a light emitting layer formed on an epitaxial wafer and individually cutting them out. When it is connected to the electrodes and can be used separately, it is called an LED chip.

Single LED chip emits only one color. This is because only one layer emitting Red (R), Green (G), or Blue (B) is formed on the epitaxial wafer.

Unlike this method, Lumens technology simultaneously implemented RGB on one epitaxial wafer. Red (R), green (G), and blue (B) layers are piled up at once to form a 'One-Chip'. An official from Lumens said, "We named it 'Monolithic' meaning that it was made from a single piece."

The effect of stacking RGB will improve usability and productivity. As an example, a dramatic reduction in the manufacturing of micro-LED displays can be expected.

Micro-LED displays are made of millions of micro-LED chips. This is because three R, G, and B chips are needed only to make a single pixel, the smallest unit of a display.

If millions of micro-LEDs are used, the manufacturing cost becomes expensive, and attaching (transferring) can be very complicated and take a long time, but it can be reduced by one-third through one-chip operation.

A company official explained, “In the past, it took three transfer processes to make one pixel, but since R·G·B are produced from one chip, it only takes one transfer process. We can reduce the number of wafers to one sheet, so users can reduce production cost and shortening process time.”

Lumens added that it changed the red LED material to implement this technology. The red color of existing micro-LED contained gallium arsenide. This ingredient is vert different in properties from the blue and green materials, making it difficult to handle and stack.

Lumens explained that they changed the red LED material to an indium gallium nitride (InGaN). The red LED containing indium gallium nitride material is the same material as the blue and green LED, so it is easy to handle and advantageous for one-chip production.

Lumens announced that the micro-LED epitaxial wafer will be useful for implementing micro-LED TV and extended reality (XR) devices, and plans to promote commercialization.

Lumens is a first-generation company in the domestic LED industry. They mainly made backlight unit (BLU) for LCD TV. After experiencing recent ups and downs due to deteriorating market conditions, they made the turnaround through the sale of land at the headquarters and restructuring of subsidiaries. They plan to nurture micro-LED as a new growth engine.

By Staff Reporter So-ra Park (srpark@etnews.com)