Wacker has introduced a customized silicone for EV batteries. Silicone is a synthetic polymer composed of silicon, oxygen, and other natural components, and is resistant to extreme temperature changes. It plays a role in maintaining the optimum battery temperature and increasing stability in EV. Demand for high-performance materials is also rising as global EV vehicle sales have more than doubled compared to last year.

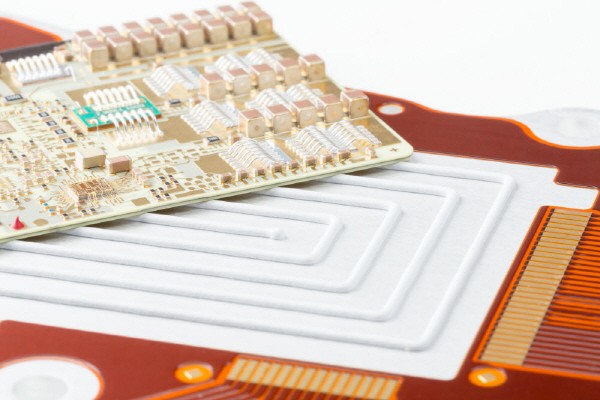

Wacker developed a silicone solution optimized for EV based on their existing silicone portfolio such as ELASTOSIL, SEMICOSIL, and SilGel. Silicone is applied in various forms such as gap fillers, gels, adhesives, and pastes to effectively manage heat.

Silicone is considered a material that demonstrates excellent performance in thermal management of EV batteries. EV mainly uses lithium-ion batteries as a power source, and the batteries are installed under the seat. A gap filler with thermal conductivity is required to effectively transfer the heat generated from the battery module to the heat cooling system of the pack. Wacker developed a gap filler that does not generate bubbles during filling to maximize heat radiation in a small space of only a few hundred micrometers (㎛). It has high flowability and fast application, maximizing production efficiency.

Silicone solution also increases battery safety. Wacker’s silicon-based coating is applied to the inside of the battery housing and becomes ceramic when exposed to heat. A ceramic layer with a thickness of only a few millimeters (mm) withstands temperatures of over 1000 degrees. It prevents melting of the housing to secure the safety of the EV battery.

In addition, Wacker also introduced silicone solutions used in battery gaskets, coolant connectors, and heat preventing seat covers.

Silicone is also considered an eco-friendly material. Silicone does not emit toxic fumes and achieves long product life and stability. In the event of a battery fire, even if silicon burns, non-toxic water, carbon dioxide, and silica will be generated, making it safer than other materials.

Wacker is collaborating with major automakers in Germany, Korea, and Japan to apply silicone solutions to various products. They are developing various innovative solutions in line with increasingly strengthened safety and environmental regulations.

By Staff Reporter So-ra Park (srpark@etnews.com)