LG Chem is investing 4 trillion won to build the largest cathode material plant in the United States. It responds to the demand for high-performance electric vehicle batteries with an annual capacity of 120,000 tons. It seems to be an attempt to break through the U.S. Inflation Reduction Act (IRA) with the establishment of local factories.

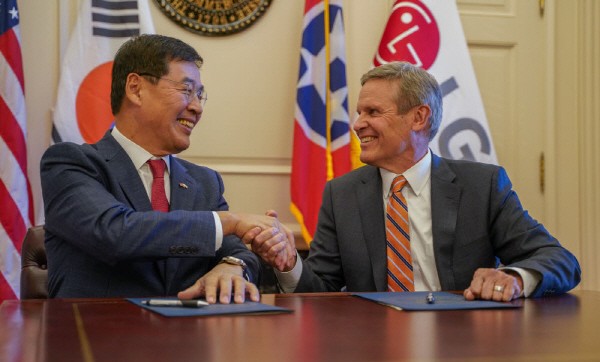

On the 22nd, LG Chem exchanged a memorandum of understanding (MOU) for the construction of the cathode material plant in Tennessee, USA. Vice Chairman Hak-Cheol Shin of LG Chem, Governor Bill Lee of Tennessee, Department of Economic and Community Development Commissioner Stuart McWhorter, and other officials participated in the signing ceremony. Construction of the Tennessee plant will begin in the first quarter of next year, and mass production will begin at the end of 2025. Plans are to expand production lines by 2027.

LG Chem will produce high-nickel quaternary alloy (NCMA) cathode materials for electric vehicle batteries at the local plant. The NCMA (Nickel Cobalt Manganese Aluminum) cathode materials have both output and stability through the increase nickel content to 80~90% and application of aluminum.

LG Chem is actively responding to changes in the global supply chain such as the U.S. IRA through its cathode material plant in Tennessee. Once the IRA is implemented, LG Chem is expected to receive tax benefits from the U.S. government when producing materials. LG Chem is also promoting cooperation in the supply of raw materials so that global automakers can meet the IRA’s electric vehicle subsidy criteria.

Vice Chairman Hak-Cheol Shin said, “The cathode material plant in Tennessee will become a key base for the next-generation battery material business as one of LG Chem’s axes of future growth. We will leap forward as the world’s top comprehensive battery material company by actively responding to the rapidly changing battery material market and global customer demand.

Reporter Ji-Woong Kim (jw0316@etnews.com)