25% rise in price next year due to supply shortage

Scarcity in automobile semiconductors and other rising demands

Up to 7 times the amount to be delivered… crisis with 'setbacks in production'

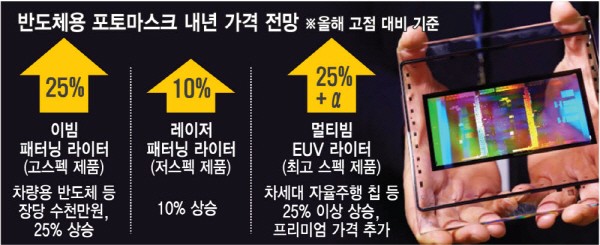

There is an emergency in the supply of photomasks essential for semiconductor manufacturing. There are concerns that the shortage in supply next year will lead to up to a 25% rise in price and delays in delivery. As the photomask supply crisis compounds, orders are piling up in key companies like Photronics (formerly PKL), Toppan, Dai Nippon Printing (DNP), and TMC, and prices are soaring. The industry is predicting that compared to the peaks this year, costs of photomasks will rise by at least 10% and up to 25% next year. It is unusual for the price of photomasks to rise during an economic downturn for memory semiconductors. This is because the rising demands are centered around system semiconductors. It has been said that they have become to obtain even with extra payment.

The shortage of photomasks results from the rise in demand for system semiconductors, specifically high-performance integrated circuit (IC) semiconductors like the ones used in automobiles and autonomous driving. Photomasks are used when etching circuit patterns on silicon wafers, a raw material. The shortage of photomask thus leads to setbacks in semiconductor production.

The delivery of high-spec products which used to take an average of 7 days has suddenly risen by over 4~7 times to now take 30~50 days. The delivery time of low spec products have doubled compared to normal. An official of a semiconductor company said that, “The delay in delivery of manufacturing equipment like photomask e-beam patterning lighters for semiconductors have caused delays in mask delivery to continue and the rise in product costs continue.” Foundry companies that produce semiconductor IC are responding to the supply of photomasks by increasing the quantity of outsourced supplies from partners.

There is a big chance that this will lead to setbacks in semiconductor production. In particular, a sudden rush of demand in front-end process development from foundry companies are expected to delay production and simultaneously raise foundry prices. The supply of semiconductors for applications like automobiles, which had recently started being solved, might slip back into a supply shortage.

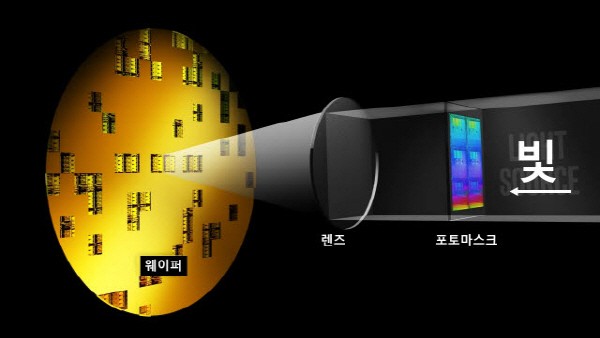

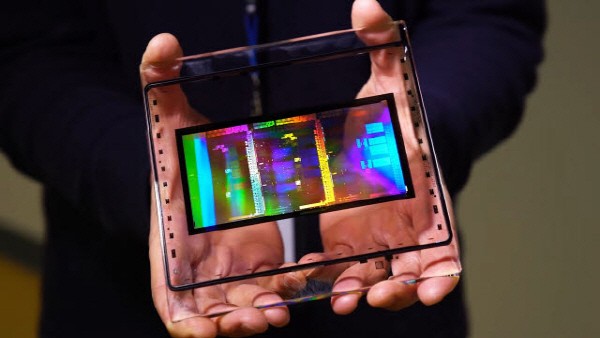

◇<Terminology> Photomask = Semiconductor circuit patterns formed and inscribed onto a board made by processing high-purity quartz. Acts as the film, the original photographic plate. They are made to be bigger than semiconductor circuits to draw minute circuits. They etch the semiconductor circuit design onto a wafer by passing light through the photomask and scaling it down with a lens.

By Staff Reporter Jiwoong Kim (jw0316@etnews.com)