Korean liquid hydrogen and special gas solution startup, Parity, has developed technology for the mass production of high purity neon using a cryogenic cooling method. High purity neon is a necessary gas in the semiconductor manufacturing process but had relied on imports for supply. Parity revealed on the 3rd that they had developed a high purity ‘neon separation system’, and that they had established a production pilot line at the factory in Nonsan. Parity’s neon separation system uses a direct cryogenic cooling method that can reach -230℃~-250℃. Using the technology independently developed by Parity, neon gas with a high purity of 99.9999% (6N) can be extracted. Compared to existing neon gas production methods, it greatly reduces the time and cost required.

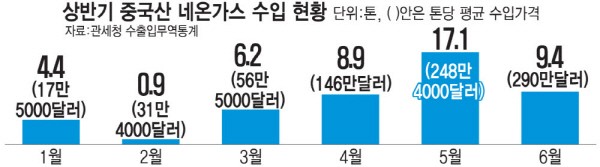

It has applied for 6 related patents. Once the mass production line is established next year, it can produce 100k~150kg of high purity neon gas every day. This reaches half of the amount of neon gas that Korea imported from China in the first half of the year. Neon gas is extracted by separating gases like nitrogen, argon, and oxygen from gases capturing in steel manufacturing processes. The key technology is in separating the ultimately remaining neon and helium. Previously, neon had to be manufactured by absorbing and refining helium from a neon and helium gas mixture (raw material)orby separating and refining gases and liquids with high pressure.The absorption and removal method had a high manufacturing cost due to needing to repeat numerous processes multiple times, and onlyproduced a small amount of high purity neon. It also required a high amount in equipment investments due to the necessity of a high quantity absorber. The high-pressure method also required multi-stage compressors and complex heat exchange structures, making its manufacturing inefficient.

Parity utilized an independent cryogenic technology. They applied the liquid hydrogen cooling technology on special gas separation.The raw material can be liquified through direct cooling to separate neon. Sasoon Kim, CEO of Parity, saidthat, “The freezing point and boiling point of neon gas is only 2~3 degrees apart, and requires precise temperature control,” and explained that, “The technology accumulated from liquifying hydrogen allows the efficiency of neon distillation to be maximized.”

Parity expects the mass production of neon gas to massively reduce the reliance on imported neon gas by 80~90%. They are going through discussions to establish a large-scale air separation unit (ASU) company and raw material supply channels. They will complete high purity neon gas sample tests and establish a supply chain for production, sales, and distribution within this year. They will attempt to mass produce not just neon, but other special gases for semiconductors, such as krypton(Kr) and xenon(Xe) as well.

◇Glossary of Terms

Neon gas= Special gas used in the exposure process of drawing semiconductor circuit patterns. A raw material for excimer laser. The domestic production of high purity (6N) neon gas used for semiconductor manufacturing processes is low and relies on imports. In the past, much of it was imported from Russia and Ukraine, but due to the Russia-Ukrainian War, the reliance on China has risen drastically. The price of neon imports of this past June has risen by 50 times compared to the same time of the previous year.

By Staff Reporter Dongjoon Kwon djkwon@etnews.com