Discussions to supply 60 global companies

Aims to increase sales by 50% by 2025

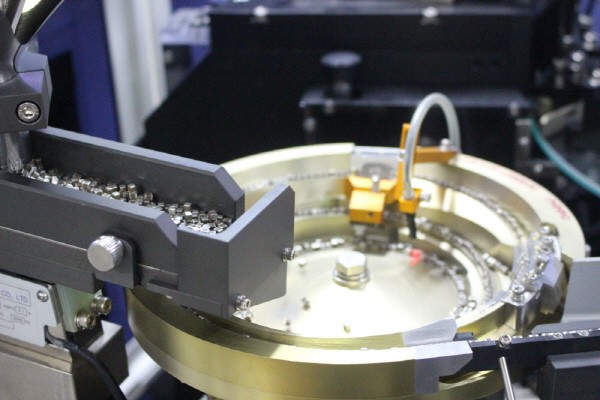

The Amotech Multilayer Ceramic Capacitors (MLCC) Production base in Namdong Induspark Complex, Incheon, on the 11th. All MLCC production facilities were in full operation, as if summer was not vacation season. The environment of a clean room stood out comparable to a semiconductor production line. A full-body dust jacket and press down on a hat had to be worn to enter.

More than 3 billion MLCCs can be produced per month at Amotech's Incheon MLCC production plant. Although the MLCC business first started in 2018, Amotech was recognized for the quality of its products, having received 'love calls' from dozens of global companies. Amotech received a number of product approvals from global EV manufacturers and European telecommunication equipment manufacturers in the first half of the year. Mass production will begin in the second half of the year.

The MLCC production line has implemented an advanced process that can temporarily halt the machine, even in cases where the machine is accidentally touched. It is possible to feel the effort the company has put into making the world’s best MLCC.

Although Amotech is new to the MLCC market, its internal engineering is not easily breakable, having developed multi-layer chip varistors for more than 20 year that have similar manufacturing processes to MLCCs. The company has accumulated know-how in manufacturing process technology, able to make its own MLCC materials.

Incheon Namdong Induspark production capacity is now lacking. It is necessary to invest in large-scale production facilities since there are ongoing discussions on supplying more than 60 global companies. Amotech is pushing to expand its MLCC line in Vietnam and is considering converting the Vietnamese production plant, originally operated by the company, into MLCC. In the long term, the Seoul and Incheon plants will focus on MLCC R&D and ultra-small MLCCs, and the Vietnam plant on mass production.

Amotech put all its heart and soul into expanding the MLCC business for EVs. Its core competitiveness can be seen in the electronics market, and it has high market growth and profitability.

The technology that is needed to combat high temperature and high voltage has become important due to the increase in the power used in the vehicle as the EV and autonomous vehicle markets develop. Amotech is equipped with the core technology. It has secured a body composition that can implement various high temperature conditions, high pressure, and high capacity required by customers.

An excellent MLCC function can be implemented through insulating materials and fine grain materials that allow uniform crystal control in a high-temperature environment. This is possible due to the competitiveness that Amotech has accumulated for more than 20 years from manufacturing ceramic parts that handle high voltage. The company is able to respond flexibly to customer needs by developing various special MLCCs necessary for the growing market.

According to Amotech director Moonsu So, “In the early stage of entering the market, Amotech will target the MLCC business centered on a niche, then stand out in the automotive MLCC field with product power comparable to that of a global company in the mid-to-long term stage.”

MLCC has emerged as the future driver of Amotech. The company has set a goal of increasing MLCC sales by 50% by 2025. The goal is to maintain double-digit margins in the long term once the mass production yield is stabilized.

Director So said, “We will focus on specialized products with Amotech’s unique competitiveness in the newly growing MLCC market. Our goal is to become a specialized MLCC company.”

Incheon=

By Staff Reporter Sora Park (srpark@etnews.com)