Pulse-type new technology developed for the first time in South Korea

Current flowing through battery cell enabled repeat charging and discharging

High current experienced immediately after battery ex

KNC (CEO Hyung-cheol Kim), a company specializing in semiconductor and display automation equipment, has developed pulse-type battery formation equipment for the first time in South Korea. Using this equipment can shorten the activation processing time by three to four fold compared to now, and it has an advantage in securing durability since the battery experiences a high current for the first time immediately after its exterior is fitted.

Battery production processes can largely be divided into △electrode process, △assembly process, and △formation process. Battery cells are finished after the formation process which activates the battery to generate electricity is completed.

KNC's formation equipment is used in the formation process, and it functions as a secondary battery while repeatedly charging and discharging by flowing current to the battery cell.

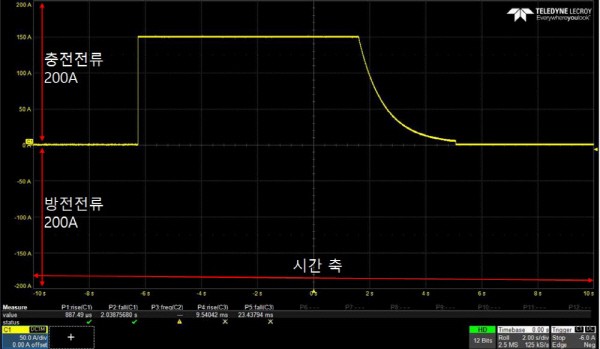

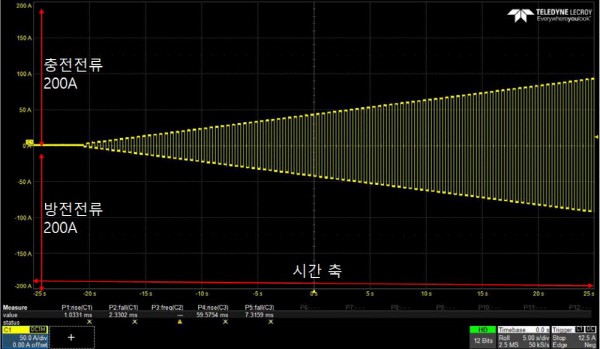

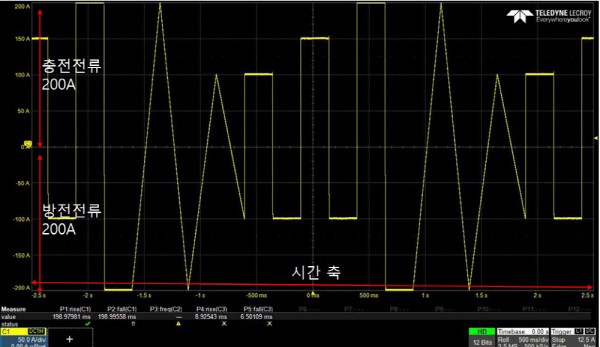

This equipment is equipped with new technology that applies the pulse method. Pulse means applying a large amplitude of current for a very short time. The company applied the technology to control the current in units of 1 mSEC to the equipment, and developed it so that the chemical reaction is accelerated faster than conventional methods and internal resistance is reduced in the process of charging and discharging repeatedly.

Existing formation equipment has a charge and discharge rate of 0.4C (2.5 hours) or 0.2C (5 hours) per battery cell, whereas this equipment can charge and discharge at 1C (1 hour). 1C refers to the current value that can be charged and discharged for 60 minutes. In the end, it is designed with the pulse method and current control technology that is safe even if a higher current value than existing formation equipment is applied. In addition, if a high current value is applied, the formation (charge/discharge) process time can be significantly reduced.

This equipment also has the advantage of reducing internal resistance because it repeats charging and shallow discharging. If internal resistance is reduced, it is advantageous for securing battery cell durability since the new battery experiences a high current in the initial activation process. This is similar to the principle of developing a kind of immunity during the process.

This equipment has been developed as a mass-production model, and has been developed to be applicable to all form factors such as cylindrical, square, and pouch. The company is currently in discussions to supply leading domestic battery manufacturers.

Byung-gil Yoo, Executive Vice President of KNC, said, “Pulse-type current control technology has the advantage of not only enabling faster activation than before, but also increasing battery cell durability," adding, “Current equipment may be exposed to deterioration due to increased internal resistance without experiencing high current charging until after it is delivered to consumers." He further added, "If internal resistance is increased, durability may decrease, and there is also a risk of shortening the half-life."

By Staff Reporter Tae-jun Park gaius@etnews.com