As LG Energy Solution and General Motors (GM) of the United States confirmed the construction of the third electric vehicle battery joint plant, and they have secured an annual 160GWh joint plant in the United States alone. With global automakers declaring the internalization of batteries one after another, LG Energy Solutionhas secured a solid future growth engine.

LG Energy Solution held an investment announcement event in Lansing, Michigan, USA on the 25th (local time) and announced plans to establish a third joint plant of 'Ultium Cells', a joint venture with GM. The total investment is about 3 trillion KRW (2.6 billionUS dollar) and is expected to be completed in the second half of 2024.

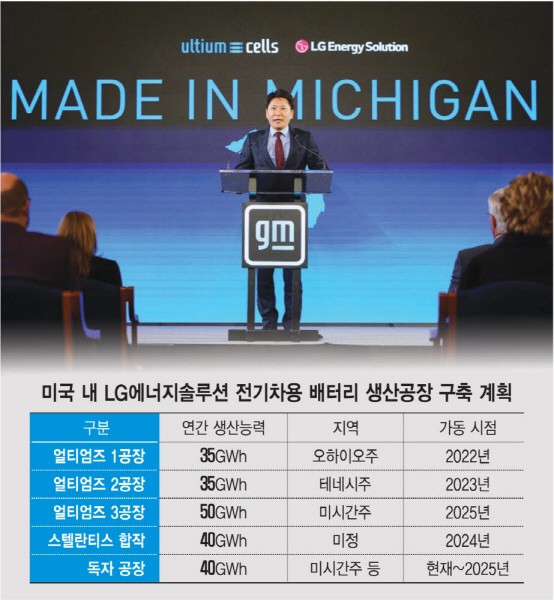

Construction of this new plant will start this year and mass production will begin in the first phase in 2025. With an annual production capacity of 50GWh, it will be the largest single plant in the United States. Ultium Cells has the first plant (35GWh) in Ohio and the second plant (35GWh) in Tennessee. The first plant will start mass production this year and the second plant in 2023. The two companies plan to gradually expand the production capacity of the two plants, and including the third plant in the future, will secure an annual production capacity of 120GWh or more by 2025.

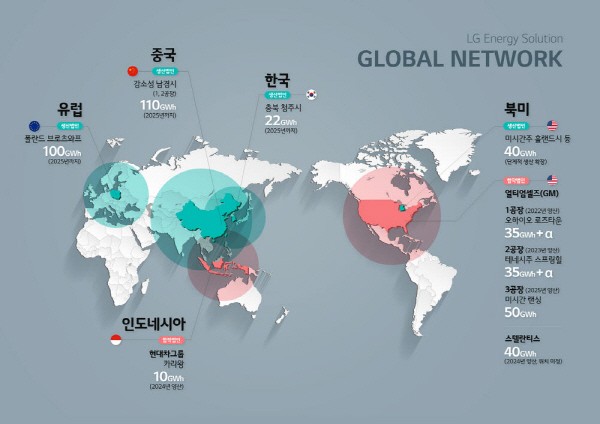

In addition to the GM joint plant, LG Energy Solution established a 40GWh electric vehicle battery joint venture with Stellantis, another American automaker. The factory is currently under final review of candidate sites, and construction is scheduled to begin in the second quarter of this year and production in the first quarter of 2024. Including the 40GWh plant, which is being further expanded by 2025, the battery joint venture and independent production capacity built by LG Energy Solution in the US will reach at least 200GWh per year. This is the amount of batteries that can produce 2.8 million electric vehicles per year (based on Hyundai’s IONIQ 5). It is the largest battery production base to be built in one country and region across the global automobile and battery industry.

As LG Energy Solution secured a 200GWh battery joint venture and independent factory in the US alone, they have established a firm independent profit structure despite the global automobile industry's craze for internalizing batteries.

Tesla, the No. 1 global electric vehicle sales volume, and Toyota and Volkswagen, the No. 1, 2 global manufacturers of internal combustion engine cars, declared their internalization of battery, which would threaten the existing battery companies.

Toyota announced that theywill internalize 200GWh batteries per year by investing 16 trillion KRW by 2030, and Volkswagen will also build 6 factories by 2030 in Europe to gain 240GWh battery capacity.

LG Energy Solution CEO (Vice Chairman) Young-soo Kwon said, “The 3rd joint factory of Ultium Cells will serve as a gateway to the birth of millions of electric vehicles in the future. With GM where we have been building a long-term cooperative relationship, we will greatly contribute to the transition to the era of electric vehicles in the United States.

According to global market research firm IHS, the North American electric vehicle battery market is expected to grow from 46GWh in 2021 to 143GWh in 2023 and 286GWh in 2025.

By Staff Reporter Taejun Park (gaius@etnews.com)