Sang-A Frontec develops PTFE nanomembrane

EverChemTech localizes anti-static nano coating solution

CIS Chemical develops a material for secondary battery separator coating

The number of cases of localization has significantly increased by using domestic nano technology in various industrial materials that were depended heavily on imports. Nano Korea 2021 provide an opportunity to see companies that succeeded in independent material technology based on their own nano technology. It was an opportunity to reaffirm that nanotechnology is one of the pillars supporting Korea’s industry.

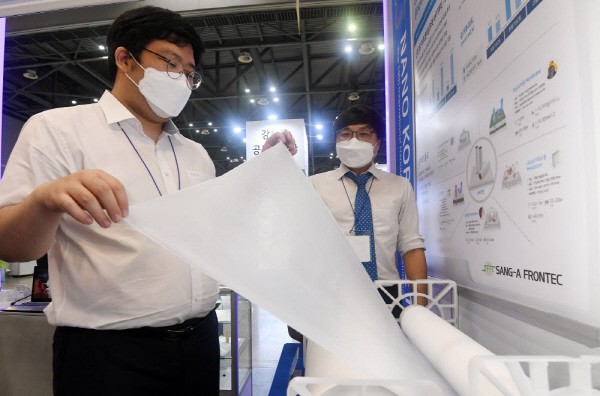

◇ Sang-A Frontec develops PTFE nanomembrane to replace US Gore materials

Sang-A Frontec has domestically developed 'Polytetrafluoroethylene (PTFE) nano membrane'. PTFE nanomembrane is a material that U.S. Gore has taken over most of the market and is heavily dependent on imports.

The PTFE nanomembrane developed by Sang-A Frontec expanded the PTFE raw material, which has excellent chemical resistance and heat resistance, to make a 20 micrometer-thin film. Micropores at the nano level are created by pulling and stretching the membrane, which air can pass through whereas water cannot. The membrane can be used for filters in air purifiers or ventilation (vent) parts for vehicles with its property.

For instance, dew condensation may occur, and water droplets can form inside the car lamp. Applying PTFE nanomembrane material to the parts where the lamp and vehicle are fastened can solve this condensation phenomenon.

The application of PTFE nanomembrane material for medical use is very high. It is used in dentistry as an anti-adhesion material that prevents the gums from digging into the empty space after tooth extraction or as an implant inserted into the gum. Most of the medical PTFE nano membrane products are also imported from the United States or Japan.

Sang-A Frontec has developed a medical PTFE nanomembrane material and is currently awaiting approval from the Ministry of Food and Drug Safety. An official from Sang-A Frontec said, “PTFE nano membrane can be used in various fields such as electronics, water treatment, air filters, functional clothing, and medical materials. With this localization of the three-dimensional (3D) porous PTFE nano-membrane material, we will be able to minimize our dependence on imports.” Sang-A Frontec is supplying PTFE nano membranes abroad such as Europe.

◇Localization of EverChemTech’s anti-static nano coating solution relieves from relying on imports

EverChemTech introduced an anti-static coating solution for protective and release liner films. In the past, the material relied on Japanese imports.

Liquid crystal display (LCD) or light-emitting diode (LED) displays must prevent static electricity during charging. This is due to distortion that can occur from screen frequency interference. Such a display protection and release liner film should be very thin, easily peel able, and resistant to contamination and abrasion.

EverChemTech is expected to have an import substitution effect by localizing a high-functional anti-static nano coating solution that can prevent the release liner film from charging, and protect from contamination and abrasion.

EverChemTech 's nano coating solution is characterized by excellent adhesion to the display and great abrasion resistance, chemical resistance, and antifouling properties while being thin. EverChemTech's organic/inorganic material reforming technology and blending/dispersing technology contributed to improving the performance of the nano coating solution. The company was able to implement outstanding optical properties of the coating solution by optimizing the manufacturing process.

EverChemTech has commercialized anti-static coating solutions by supplying them to large domestic chemical companies that manufacture films. An EverChemTech official said, “Anti-static nano coating solution will be used in many fields that need displays, such as smartphones and tablet PCs as well as TVs.”

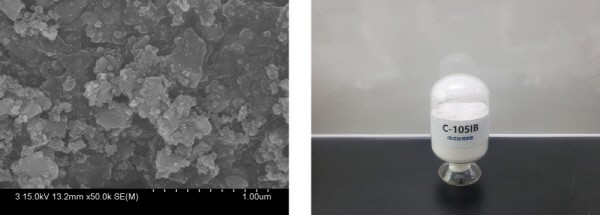

◇CIS Chemical localizes ‘Aluminium oxide', a secondary battery separator coating material that relied on Japanese imports

CIS Chemical succeeded in localizing 'alumium oxide' for secondary battery separator coating. The polymer separator for secondary batteries is weak and may be deformed by heat. The separator may shrink and lose its function at temperatures above 100 degrees Celsius. Alumium oxide complements the weak polymer membrane mechanically and thermally.

It is coated with alumium oxide powder, made of ceramic particles, to strengthen the separator. This coating film prevents mechanical shrinkage of the separator to maintain stable performance.

Since the separator itself is as thin as a micrometer, the alumium oxide powder coating must be as thin as nanometers.CIS Chemical has reduced the median size of alumium oxide powder to 100 nanometers. This was possible due to the company's nanoscale microprocessing technology. CIS Chemical has also secured a technology to mass-produce nano-sized alumium oxide powder stably.

It is expected that dependence on foreign countries will be greatly reduced as CIS Chemical localizes alumium oxide powder for separator coating. Alumium oxide for secondary battery separator coating has been entirely imported from Japan, such as Sumitomo Chemical.

By Staff Reporter Dongjun Kwon

(djkwon@etnews.com)