Korea Advanced Institute of Science & Technology (KAIST, President Shin Sung-chul) has developed high-efficient electrode based on glass fibrous membrane that will solve many problems of current lithium-sulfur batteries. It is expected that this new electrode will be widely used for development of high-tech secondary batteries such as batteries for electric vehicles as it is able to improve low electric conductivity and reduced lifespan of lithium-sulfur batteries.

National Research Foundation of Korea announced on the 31st that a research team led by Director Kim Do-kyung of KAIST EEWS Research Center has developed high-efficient electrodes for lithium-sulfur batteries by using glass fibrous membrane, which is eco-friendly and cost-effective.

Lithium-sulfur battery is seen as a next-generation large-capacity ESS (Energy Storage System) as it has excellent capacity and energy density compared to lithium-ion batteries that are currently used often.

However electric conductivity of sulfur that is used for a battery is low and volume of a battery tends to change during charge and discharge. Also it was difficult to commercialize lithium-sulfur battery as batteries were damaged during a reaction process of lithium and sulfur.

Although industries had tried to solve problems by using electrodes that are based on conductive carbon material, they did not see much success. Rather energy density of a battery was impeded due to a need for adjuncts such as a binder or a metallic current collector. Also electrode material was separated from a battery due to lack of flexibility.

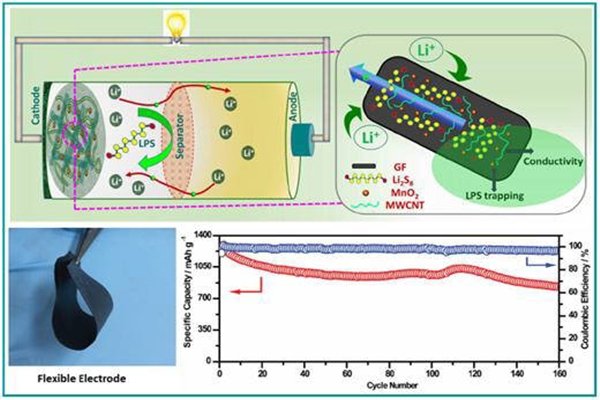

Research team was able to solve problems by developing flexible porous electrodes by using glass fibers. Because this electrode is able to operate smoothly without a metallic current collector, it does not impede with energy density.

Due to its high flexibility, electrode does not get separated easily even from external impact. Research team also added carbon nanotube and manganese oxide to glass fibrous membrane in order to prevent reduction of electric conductivity and performance of a battery.

Energy density of this lithium-sulfur battery is 1,210mAh per gram which is six times higher than energy density of a current lithium-ion battery. It also maintained energy density of 970mAh even through 100 cycles of charge and discharge.

“It is now possible to mass-produce and commercialize lithium-sulfur batteries by developing a manufacturing method for high-efficient electrodes.” said Director Kim Do-kyung. “They will be able to maximize capacity of stored energy by being applied to electric vehicles in the future.”

Staff Reporter Kim, Youngjoon | kyj85@etnews.com