South Korean research team converged fabric with OLED (Organic Light Emitting Diode) and developed flexible clothing-type wearable display technology. It will not be long before people get to see a wrinkled screen on type of clothing.

Korea Advanced Institute of Science & Technology (KAIST, President Shin, Sungchul) announced on the 24th that a research team led by Professor Choi Kyung-chul of Electric and Electronic Engineering Department developed clothing-type organic light emitting device, which is implemented through luminous fabric that uses fabric instead of glass as basis for display device and that result of his research was published online in July through an international scientific journal called Scientific Report.

Research team has been working on implementing display on top of fabric after forming luminous body on top of fabric in 2011. It had had difficulties in commercializing clothing-type organic light emitting diode due to rough surface and flexibility of fabric.

Research team succeeded in operating organic light emitting diode with thickness of hundreds of nanometers on top of fabric through heat sealing flattening technology in 2015. In 2016, it developed macromolecular luminous device that still has high brightness on top of thin fiber by using dip-coating technology that pulls out threads from a solution at an uniform speed.

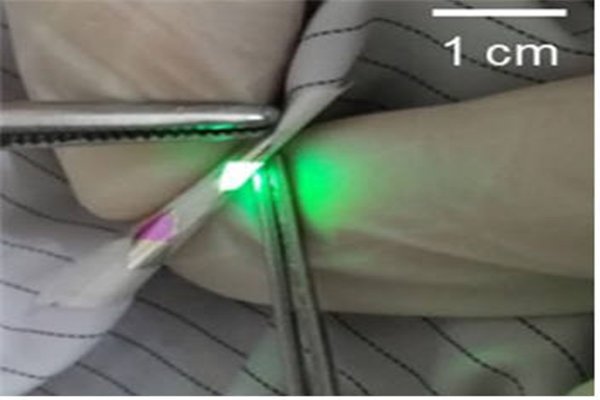

This clothing-type organic light emitting device is developed through researches in the past and has the best electro-optic characteristics. It even operates in circumstances where radius of a curve is only 2mm and is the most flexible device out of all luminous devices that are based on fabric.

Research team weaves fabrics with materials that are resistant against heat and formed flattened layers through heat sealing. It then applied transparent flexible OLED and encapsulation technology, which are developed through its own technologies, to flattened layers and succeeded in developing clothing-type organic light emitting device.

Utilizing light reflex between two electrodes, OLED is designed so that it maximizes efficiency of light source by utilizing micro-cavity effect that improves light extraction of particular bandwidth and phosphorescent photic layers that increase efficiency of materials in converting optical energy. This new OLED lowers loss of light through transparent and flexible OLED encapsulation technology and has lifespan and flexibility of a display device.

Weaved structure and empty space within fabric greatly lower mechanical stress that is applied to organic light emitting device.

“It will not be long before people get to see displays implemented on top of clothing.” said Professor Choi. “Not only this device will have huge impact on fashion and e-textile but it will also have huge impact on automotive industries and healthcare industries such as light therapy.”

Staff Reporter Kim, Soonki | soonkkim@etnews.com