South Korean business has developed a material that can dramatically improve max range, power, and stability of electric vehicles after doing research for 8 years. It is drawing interests from other industries as it was able to receive certifications from a global automotive manufacturer.

ILJIN Materials announced on the 18th that it has developed ‘I2S’, which is Elecfoil for next-generation electric vehicles, and that it is currently selling I2S to automotive manufacturers.

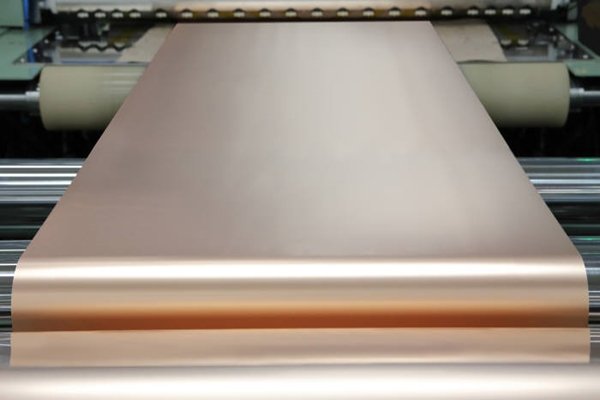

Elecfoil is a thin copper plate with thickness of less than 10µm and is made by electrolysis of copper sulfate solution. It plays a role of a current collector that forms cathode for a battery and is classified as an important material that is absolutely needed for secondary batteries.

Elecfoil developed by ILJIN Materials can withstand higher temperature and higher pressure than current Elecfoil.

According to industries, secondary battery manufacturers are working to develop high-capacity and high-power batteries in order to improve max range and power of electric vehicles. In order to implement high capacity and high power, material that can withstand high temperature and high pressure that occur during manufacturing of batteries is a must. While development of batteries is impossible without this material withstanding high temperature and high pressure first, ILJIN Materials has made it possible through development of I2S#.

“Industries have been requesting for improvement of properties of Elecfoil in order to develop high-capacity batteries.” said a representative for ILJIN Materials. “We were able to develop Elecfoil with higher heat-resisting property and pressure-resisting property by adding our new solution material to current manufacturing process of Elecfoil.”

ILJIN Materials, which is the top Elecfoil manufacturer for electric vehicles in the world, had invested 8 years in developing I2S. Because technologies that are on different dimension were needed to develop I2S, ILJIN Materials invested capabilities from its entire company. It explained that I2S was developed through advanced and state-of-the-art technologies and that secondary batteries will be able to make ‘quantum jump’ in performance due to I2S.

ILJIN Materials announced that it received certifications from a foreign global automotive manufacturer and it is heard that its Elecfoil is going to be used for an European automotive manufacturer’s next-generation electric vehicles. It already started delivering some of its Elecfoil and is likely to supplying Elecfoil on full-scale starting from next year.

“Because I2S is integrated with cutting-edge technology, it is a material with high entry barrier.” said CEO Ju Jae-hwan of ILJIN Materials. “It is very meaningful for us to grab upper hands in future material markets.”

Major technology for Elecfoil is having Elecfoil have electric properties while maintaining thin and uniformed surface as much as possible. After going through more than 20,000 trials and errors from 1984, when it started developing Elecfoil, to 1997, it finally succeeded in developing its own technology. Through this technology, it holds 20% of shares of global Elecfoil markets for secondary batteries and is the top Elecfoil manufacturer in the world. In order to build its dominance even more, it is planning to increase its production capacity from 14,000 tons per year up to 24,000 tons per year. It is expected that it will be able to grab upper hands in future markets as it develops new material on top of its current dominance over Elecfoil markets.

Staff Reporter Lee, Youngho | youngtiger@etnews.com