Transparent electrode film material, which has resistance change of around 3% even when it is folded and unfolded repeatedly for 500,000 times, has been localized. Japanese businesses’ transparent electrode films that are currently commercialized can be folded and unfolded about 100,000 times. This new transparent electrode film material is seen as an innovative technology that will push forward commercialization of foldable displays.

N&B Co., Ltd. (CEO Kim Sang-ho) announced on the 9th that it has developed transparent electrode film material called ‘Flexionet’ which has curvature of 1R and resistance change of 3.8%.

Curvature indicates how much an area is bent. 1R indicates the amount of folding by a circle with a radius of 1 mm. As value of curvature becomes lower, folding becomes more complete. Transparent electrode materials that are commercialized by Japanese businesses have curvature of 3R.

Flexionet utilizes a technology that connects silver-nano lines with photonic sintering technology within multi-wavelength area. It shoots particular light when connecting silver-nano lines and it connects silver-nano lines by only affecting them and not affecting other areas. This technology lowers surface resistance and has excellent stability in folding and unfolding.

Previously when connecting silver-nano lines, resistance change was very severe due to polymeric materials and surface resistance was not even as well.

Standard resistance value that is decided by industries is ±10% when commercializing transparent electrode film materials. Flexionet has lowered resistance value to around 3%. Fact that films need to be opaque in order to increase resistance values was also resolved by N&B Co., Ltd.

N&B Co., Ltd. also made this material to be folded and unfolded up to 500,000 times. Suppose people fold and unfold foldable Smartphones between 100 to 200 times daily, Flexionet can be used for more than 5 years. Industries estimate that people generally exchange their Smartphones every 3 years.

“Flexionet can be used in many ways for touch-sensor film, OLED, and LCD electrode film.” said CEO Kim Sang-ho of N&B Co., Ltd. “We increased stability of our technology so that film manufactures, which will soon become our customers, have no problems in using flexionet to mass-produce their products.”

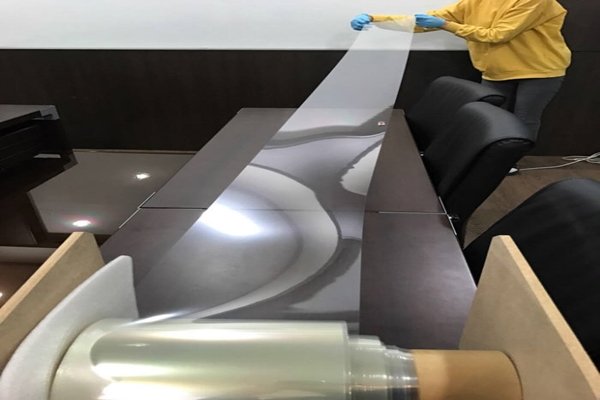

N&B Co., Ltd. has also prepared mass-production system that can produce 3 million m2 of Flexionet in a year with roll-to-roll process that can continuously produce plastic films.

N&B Co., Ltd. is currently discussing with South Korean and other film manufacturers in order to produce final mass-production products.

N&B Co., Ltd. is a venture company that was established by Professor Kim Sang-ho of Kongju National University’s Chemistry Department in November of 2011 and it completed Flexionet technology by receiving support from Nano Convergence 2020 Business Group.

“While material markets have significantly depended on Japan, we expect that our innovative technologies can create meaningful result in areas of flexible devices.” said CEO Kim. “They will contribute to meaningful commercialization of nano-technologies.”

Staff Reporter Park, Sora | srpark@etnews.com