South Korean research team has developed a technology that can reduce manufacturing time of OLED by one-tenth and it is expecting that this technology can greatly increase productivity of variety of device manufacturers that utilize thin films including OLED.

National Research Foundation of Korea (President Cho Moo-je) announced on the 9th that a research team led by Professor Yoon Hong-seok of Hanbat National University’s Mechanical Engineering Department has developed a technology that can rapidly transfer many layers of OLED by spraying high-pressure gas.

Previous OLED transferring process stripped off thin film one by one from a board. This required long time to transfer OLEDs since there were up to 20 functional layers of OLED and it also damaged thin film many times. This transferring process was the leading obstacle in mass-production of OLEDs.

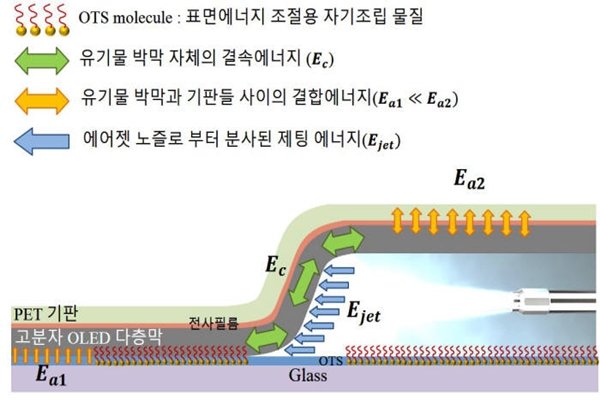

Research team used a new air jet technology that sprays desquamating gas such as nitrogen, argon, and air at high pressure. It sprays these gas at a speed of 300 meters per second between a board and OLED and reduces binding power of OLED from a board. On the other hand, it increases binding energy of layers that are trying to be transferred. This method can easily transfer thin films effectively and without any damage.

Transferred films using air jet boast high quality. Thin films that are applied with this method showed surface roughness of 5.2 nanometers whereas surface roughness of thin films that were applied with old method was 47.3 nanometers.

Research team is expecting that this technology can innovate productivity of OLED. This technology can also be applied to manufacturing of basic electronic devices such as thin-film solar batteries that utilize thin films and semiconductor devices.

“We have developed a technology that can quickly transfer OLEDs without damaging them by utilizing air jet.” said Professor Yoon Hong-seok. “Productivity of related products can be maximized by greatly reducing manufacturing cost of OLEDs.”

Staff Reporter Kim, Youngjoon | kyj85@etnews.com