Technology that can collect electricity by applying thermoelectric materials onto exterior of buildings, roofs, and exterior of cars like paint has been developed.

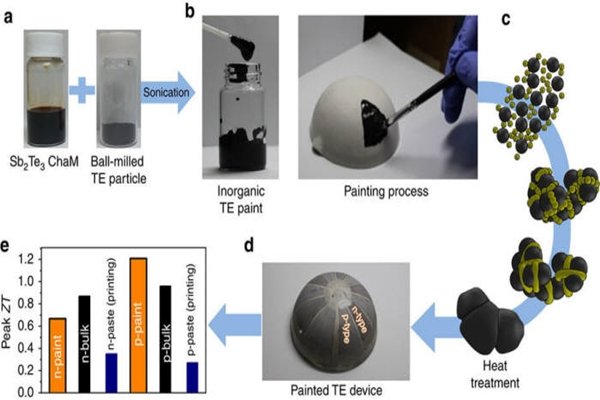

Research team led by Professor Son Jae-sung of UNIST’s (Ulsan National Institute of Science and Technology) New Material Engineering Department made an announcement on the 15th that it has developed thermoelectric material that is applied like paint and ‘painting process’ that develops thermoelectric generators with this material.

This is the first time when thermoelectric material in paint form is developed and thermoelectric generator using this material is implemented. Although thermoelectric material in ink form was developed previously, its performance was very low and it was only for printing.

Technology that is developed by this research team can be easily applied to any objects (heat source) and produce electricity.

Thermoelectric technology is a technology that chances heat energy into electric energy and vice versa. Flat thermoelectric modules are used for rectangular materials such as various small cooling devices and car engines and waste heat generators of ship.

Because heat source’s surface is not just flat, it was difficult to collect heat with previous flat materials and modules.

Research team has solved this problem with paint-type thermoelectric material. “By developing integral thermoelectric modules through painting process, we have overcome limitations of flat thermoelectric modules and are able to collect heat energy more efficiently.” said Professor Son. “Thermoelectric generation systems can be developed as whatever types user want and cost from manufacturing systems can also be greatly reduced by conserving materials and simplifying processes..”

Figure of merit of thermoelectric paint material has come out to be 0.69 (n-type material) and 1.21 (p-type material). These values are similar to figure of merit for commercialized flat thermoelectric material as its value is usually 1.0.

Curved thermoelectric generator’s electricity density was also closely measured as commercialized thermoelectric modules.

It is easy for density to be low for thermoelectric material if it is made out of ink. Research team led by Professor Son applied newly-developed ‘sintering aid’ and preserved its density from becoming lower. Not only can sintering aid, which finely holds materials together, be used for thermoelectric materials but it can also be used for energy and electronic materials. Due to this characteristic, energy source that is lost in nature by turning into heat can be recovered.

“Our thermoelectric material can be applied any heat source regardless of its shape, type and size.” said Professor Son. “It will place itself as a new type of new and renewable energy generating system.”

Professor Cho Wook, Choi Kyeong-jin and Lee Seok-bin of UNIST, Ph.D. Kwon Beom-jin, Kim Jin-sang, and Hyeon Do-bin of KIST (Korea Institute of Science and Technology) and Ph.D. Lee Ji-eun of KERI (Korea Electrotechnology Research Institute) participated in this research.

Staff Reporter Lim, Dongshik | dslim@etnews.com