A South Korean company is going to mass-produce world’s first piezoelectric MEMS (Micro-Electro-Mechanical Systems) microphones. MEMS microphones are ultra-small microphones that are used for small mobile devices such as Smartphones and headsets. If these microphones are implemented through piezoelectric method, they can made into ultra-thin and ultra-small products with waterproof and dustproof functions. This technology is considered as a ‘dream technology’ for mobile sound fields.

According to an industry on the 6th, MNtech Co., Ltd. (CEO Kim Cheol-young) has agreed to establish a joint-company called ‘Mirae VESPER’ with VESPER from the U.S. VESPER is an American start-up company that possesses technologies regarding piezoelectric MEMS microphones. MNtech Co., Ltd. and VESPER are going to invest $899,000 (1 billion KRW) and $449,500 (500 million KRW) respectively to complete establishment of their joint-company by end of this month.

MNtech Co., Ltd. and VESPER have agreed to take 66.7% and 33.3% of shares from a joint-company respectively and are going to send two and one board of directors respectively to a joint-company. Executive Director Yun Hyo-seong of MNtech Co., Ltd. was nominated as the first CEO of Mirae VESPER.

Mirae VESPER is going to mass-produce world’s first piezoelectric MEMS microphones and its goal is to establish mass-production system by end of first quarter of next year. While VESPER is going to utilize its major technologies, MNtech Co., Ltd. is going to provide its capital, sales capacity, and manufacturing technologies.

While VESPER provides MEMS dies and ASICs (Application Specific Integrated Circuits), Mirae VESPER will be in charge of manufacturing finished products. Mirae VESPER is going to start its business by targeting South Korean businesses and investing corporations of those companies. Although Chinese market is excluded from its target, South Korean markets are not small markets considering the fact that many top mobile and electronic device manufacturers are gathered in South Korea.

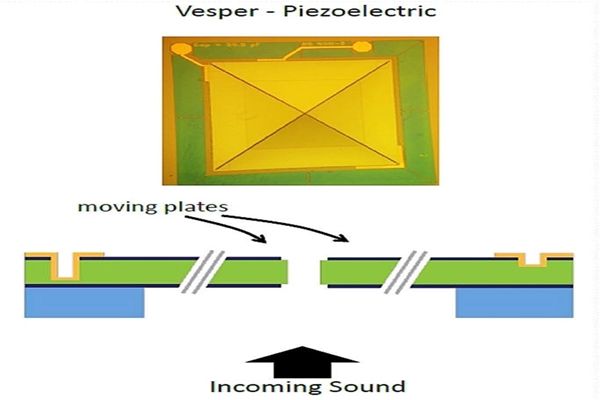

It is expected that piezoelectric MEMS microphones that are going to be mass-produced by Mirae VESPER are going to bring greater innovation to markets that are related to source of sound. If piezoelectric MEMS dies that are developed by VESPER are used, microphones that are much thinner than current capacitive microphones can be manufactured. Also response performance can be improved within 5 to 10 µs.

These microphones are also advantageous for waterproof and dustproof functions that have emerged as hot topics in Smartphone markets since they do not need diaphragms. Instead of diaphragms, they use piezoelectric materials. Even if they are not covered with waterproof and dustproof materials, they possess their own waterproof and dustproof functions through piezoelectric materials. Since structure of these microphones is also simple, they are also advantageous in reducing electricity and production cost.

Piezoelectric MEMS microphones can also be applied to devices other than Smartphones. It is expected that they will be used for IoT devices that use voice recognition function as their major input method. They can clearly recognize sound that is far away and also have outstanding function to eliminate surrounding noise. They are also advantageous in implementing ‘Always On’ function that can receive users’ voice anytime.

MNtech Co., Ltd. had highly praised VESPER’s value and had been negotiating with VESPER under the table for long time. During this process, MNtech Co., Ltd. even carried out $3.60 million (4 billion KRW) of investment. Establishment of a joint company indicates the starting point of actual piezoelectric MEMS microphone business.

Mirae VESPER’s goal is to secure an upper hand in related markets by establish world’s first mass-production system.

“Although piezoelectric MEMS microphone was considered as an impossible technology even if it has many advantages, opportunity for commercialization has opened up as VESPER has decided to share its major technologies.” said a representative for MNtech Co., Ltd. “We are going to mass-produce world’s first piezoelectric MEMS microphones by establishing a joint company.”

▲Piezoelectric MEMS microphone = Microphone that replaces diaphragm, which is used for current MEMS microphones, with piezoelectric materials that are like aluminum and improves SNR (Signal-to-Noise Ratio), start time, and response performance of MEMS microphones. Because it does not have a diaphragm, structure can be simplified. MEMS microphones are ultra-small microphones started drawing attention since Apple applied them for the first time for iPhone 5. Because they are smaller and use lesser electricity than condenser microphones, they are mostly used for Smartphones. Piezoelectric MEMS microphones are the ones that increase technologies of MEMS microphones by one more step.

Staff Reporter Song, Junyoung | songjy@etnews.com