To enter Chinese markets, APP exhibited atmospheric plasma equipment for cleaning and others at a huge display exhibition that was held in China.

APP made an announcement on the 13th of March that it would participate ‘FPD CHINA 2016’, which was held from the 15th to the 20th at Shanghai New International EXPO Center, and introduce its atmospheric plasma equipment.

FPD China, which is a global display exhibition, had 320 booths set up and 130 businesses participated in last year and had 53,900 spectators. It was predicted that there would be about 60,000 spectators this year.

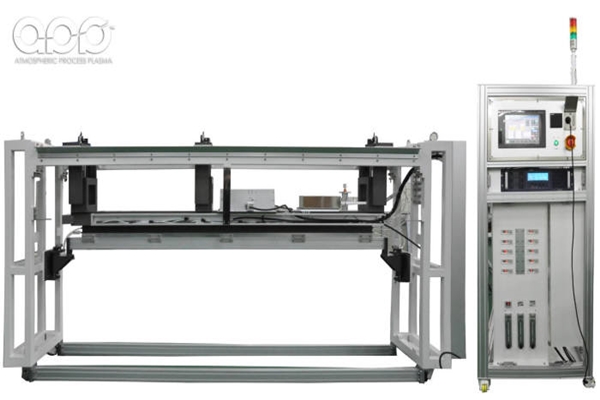

APP, which was attending this exhibition for the second time followed by last year, exhibited variety of atmospheric plasma equipment such as ultra-small plasma equipment that is easy to carry and OLED cleansing plasma equipment that does not cause particles to show Chinese markets its products.

One of the equipment that received many attention was its atmospheric plasma equipment called ‘Plami’ that is easy to carry since it only weights about 10kg. It is used to clean surface before bonding and coating, printing, and laminating processes during display and cellphone and PCB manufacturing processes. Unlike current wet cleansing that uses alcohol, it uses dry cleansing using plasma. It carefully inspects surface of a material by causing plasma in atmospheric pressure and eliminated organic materials on surface.

Unlike current plasma equipment, it is easy to carry Plami since it only weighs about 10kg. Its strength is that it can be easily attached to variety of systems that are located in production lines and it causes plasma by simply connecting power and gas. Not only Plami can be used in laboratories, but it can also be used in facilities for mass-production.

APP also introduced 10.5th generation argon atmospheric plasma equipment with large surface area to clean OLEDs. While plasma only occurred in vacuum to eliminate foreign material in metallic membrane and inorganic membrane in the past, APP’s equipment eliminates foreign material by causing plasma even in atmospheric pressure.

“Because current plasma equipment uses high voltage, particles occurred due to damage to electrode caused by sputtering.” said APP. “Because our equipment uses low-power argon glow discharge, number of particles that occur is very small compared to current N2 plasma equipment.” It can be used for processes for ductile PCB, OLED, and LCD.

“Not only was our equipment used to clean panels, but many of our equipment was also used in mobile mass-production process to increase bonding power (tensile force and cementing power).” said CEO Kang Bang-kwon of APP.

APP also introduced coating equipment. By using atmospheric plasma equipment such as SiOx coating and hydrophobic deposition and polymerization, one can coat variety of films.

“Because one can rapidly decide on a direction of testing and check results, level of satisfaction from our customers is very high.” said CEO Kang. “One can experience variety of coating and testing if he or she uses our atmospheric plasma equipment.”

APP is exporting its products to Japanese and Indian markets and it attended a film exhibition that was held in Japan in April and an exhibition that was held in Mumbai in May. It is also planning to participate in exhibitions that will be held in the U.S. and Europe.

Staff Reporter Bang, Eunjoo | ejbang@etnews.com