Samsung Display has decided to manufacture and use its own photomasks to increase more of its competitive edge for OLED products. Although its primary goal is to develop preceding technologies and use photomasks for R&D purposes, industries believe that there is a high chance that Samsung Display will increase number of photomasks that it manufactures in the future.

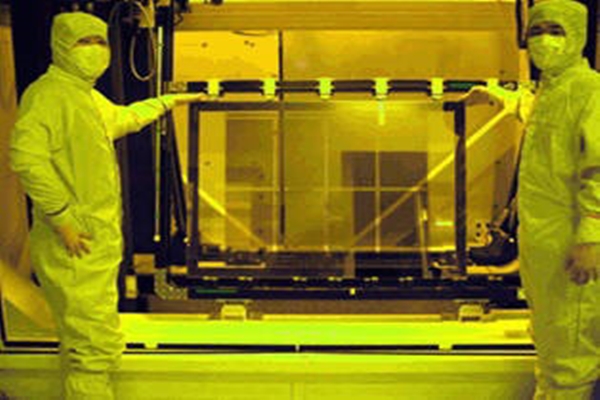

According to an industry on the 7th, Samsung Display finished manufacturing prototypes of photomasks for displays at Samsung Electronics’ photomask and started mass-producing small amount of those prototypes. To mass-produce these prototypes, Samsung Display purchased a lithography equipment.

Photomask is a necessary material that is used to design circuits during production of displays and semiconductors and is produced by carving a clean disk (blank mask) with electronic circuits after putting it into a stepper. When light is penetrated through a photomask that is placed on top of a display board or a semiconductor wafer, pattern of electronic circuits is formed and it is same principle as a development of a film with pictures.

As semiconductor processes have become more advanced and as there is an increased demand for photomasks, Samsung Electronics develops its own photomasks at its internal semiconductor laboratory and uses them. As one can deduce information about design of fine processes from a photomask, Samsung Electronics does not receive photomasks from outer businesses and produces its own for security reasons.

In early this year, prototypes of photomasks for displays were developed at Samsung Electronics’ semiconductor laboratory. Because these prototypes received positive evaluations, Samsung Display decided to mass-produce small sample of them and started mass-producing them about 3 months ago.

“We decided to manufacture our own photomasks for preceding development of OLEDs and R&D purposes.” said a representative for Samsung Display. Although Samsung Display needed to rapidly develop preceding technologies as life cycles of products had become shortened, there are times when it cannot meet the speed that it wants since it had to cooperate with outside manufacturers.

“Our primary goal is to develop high-tech technologies in advance.” said this representative. “Although we are using these prototypes for actual products, we are not producing significant amount of them and we still lack production capability to mass-produce them.”

Industries are predicting that Samsung Display will eventually decrease the amount of photomasks that it receives from outside manufacturers and increase the amount of photomasks that it produces because Samsung Display can expect to increase its competitive edge even more in markets for small and medium OLEDs that are being monopolized by Samsung Display.

Because flexible OLEDs use new material such as plastic films rather than previous glass material, knowhow on ability to form TFT pattern is very important. When a business produces its own photomasks, it can optimize technologies on photomasks and related processes. Another advantage of producing photomasks is that a business can enhance its technologies in the future and prevent its knowhow being leaked to outside businesses.

If amount of photomasks that is produced increases in the future, a business can also expect to decrease its production cost. Samsung Display already increased amount of small and medium flexible OLEDs that it produces and this amount will increase even more when Samsung Display is finished with facility investments that is currently under work.

Global photomask suppliers are making careful attentions to Samsung Display’s movements because there is a chance that the top display panel manufacturer can decrease the amount of photomasks that it purchases from outside manufacturers. Some of the global photomask manufacturers are HOYA, Toppan Photomask, DNP (Dai Nippon Printing), Photronics, and PKL.

As Samsung Display has decided to manufacturer its own photomasks followed by Samsung Electronics, there can be changes in this network of supply markets. Not only are ULCOAT, CST, and S&S Tech, which are display blank mask suppliers, supplying their products to photomask manufacturers, they have also started direct businesses with display manufacturers.

“Many panel manufacturers are considering about manufacturing their own photomasks and using them.” said one representative. “Although they are not thinking about such plan as of right now, they are slowly preparing for it as they predict that there can be a chance in network of supply markets.”

Staff Reporter Bae, Okjin | withok@etnews.com