Apple is going to apply high-tech packaging technology to RF (Radio Frequency) Chip of iPhone 7 series that will be released this fall. It is expected that iPhone 7 will become thinner and lighter and have more battery capacity. By introducing new technology, it is expected that loss of signal will also be minimized.

According to industry on the 28th, Apple is applying Fan Out Packaging technology for the first time out of all Smartphone manufacturers to ASM (Antenna Switching Module) Chip that will be loaded into iPhone 7. To carry out this technology, Apple ordered parts from Japanese ASM Chip supplier and foreign semiconductor package test (OSAT: Outsourced Semiconductor Assembly and Test) businesses.

ASM Chip is a part that is loaded into front end (area that receives signals from base station first) of RF Chip and it provides switching function that allows many frequency bandwidth signals to be sent and received with just one antenna. This is the first time when Fan Out Packaging technology is applied to major parts of a Smartphone.

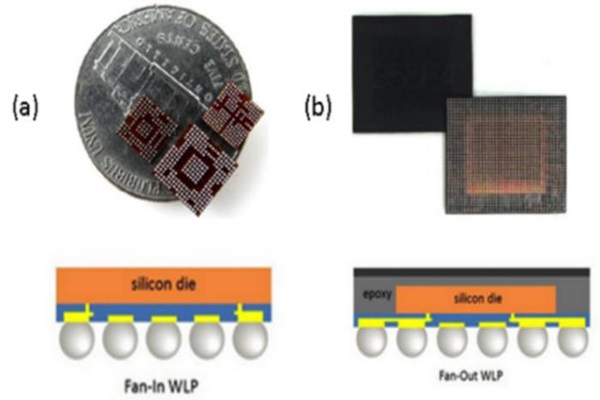

Fan Out technology is a technology that increases number of I/O (Input/Output) terminals within a package by pulling out wiring of I/O terminals to outside from a semiconductor chip (Die), which is a previous step before packaging. As area of a chip had become narrower as manufacturing processes had become finer, it was difficult to increase number of I/O terminals. Because industries do not want to increase size of a chip just for I/O terminals, they have been paying attention to Fan Out Packaging technology recently. It is most cost effective from production cost perspective if number of I/O terminals increases within a package while still decreasing size of a chip.

If Fan Out technology is applied, normal silicon chips and semiconductor compounds can be packaged together. ASM Chip that will be inside of iPhone 7 will be a chip that combines a silicon chip and a GaAs (Gallium Arsenide) semiconductor compound chip into one. GaAs semiconductor compound is widely used for RF since it is good for processing high-frequency signals. It was difficult to manufacture a comprehensive package with a silicon chip with previous technologies.

RF Chip for ASM that will be inside of iPhone 7 will not have two chips built inside of a PCB (Printing Circuit Board), but have two chips into one package. This decreases areas where parts are mounted.

“Apple has been decreasing thickness of its product and increasing battery capacity by combining each part into one.” said a representative for this industry. “One can see that Apple’s way of applying Fan Out Packaging technology to ASM Chip is a same context and this will minimize signal loss as well.”

As Apple has decided to apply Fan Out Package technology to major parts of iPhone 7, it is predicted that its competitors and new Smartphone manufacturers will also apply this technology in the future. This is a part that will be very beneficial for packaging businesses. OSAT businesses that have Fan Out Packaging technology and currently are able to mass-produce related products are StatsChipPac, Nanium and Nepes. A product that is commercialized after being produced with Fan Out Packaging technology is NXP Semiconductor’s 77GHz Radar Sensor for medium and long-distance vehicles. NXP Semiconductor applied Fan Out Packaging technology and was able to implement world’s smallest size. This product was packaged by Nepes.

Staff Reporter Han, Juyeop | powerusr@etnews.com