Oxide (Oxide semiconductor) TFT display, which its strengths are low-power design and miniaturization, is rapidly expanding its influence in market. As Apple is planning to release iPad Pro that has Oxide TFT Panel soon, it seems that it will make a sudden rise as next generation panel along with Low-Temperature Poly Silicon (LTPS) TFT.

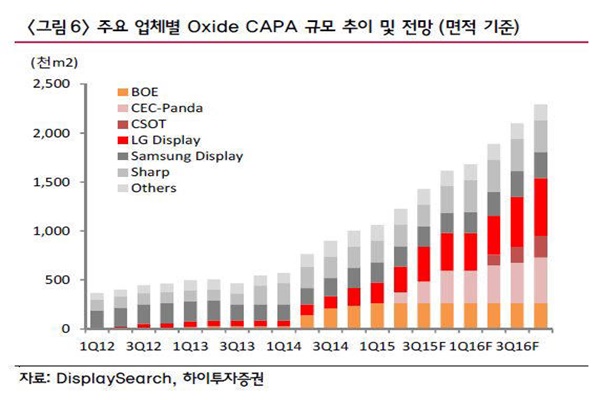

According to industry, Korean and foreign display industries are currently expanding production capabilities of Oxide TFT Panels that are boards for premium displays. They are planning to either change parts of previous amorphous-Silicon (a-Si) TFT LCD’s production lines to Oxide lines or extend them.

Because Oxide TFT Panels have faster electron traveling speed than previous a-Si TFT LCD, low-powered design is possible and battery efficiency can be maximized. Because its thickness can also be reduced up to 30% compared to previous panels, it is favorable to make finished products slimmer. It is first applied to medium and small-sized tablet PCs that can maximize its strengths.

Apple first brought this trend of changes in technologies. Apple will first apply Oxide TFT panels onto its iPad Pro that will be released in September and it is planning to apply Oxide TFT panels onto other products such as iMac and iPad and others hereafter. Korean and foreign display businesses are increasing their outputs according to this flow.

Samsung Display is currently changing its Cheonan Gen 5 (1100x1300mm) L6 Line to Oxide Line and is planning to expand its size to 100,000 sheets per month by next year from current 40,000 sheets per month. LG Display is also remodeling and expanding Oxide Lines at Paju Gen 8 P8 and P9 lines.

Sharp currently has the biggest production facilities in Japan. It is producing 30,000 sheets per month at Gen 8 (2200x2500mm) Line and is planning to extend additional lines according to Apple’s demands.

China is also planning to join trend. Chinese businesses such as BOE, CEC-Panda, and CSOT that are currently operating Pilot Lines are going into full-scale mass-production starting from this year. Chinese government is planning to expand output of LTPS and Oxide TFT-based LCDs by 5 million m2 per year.

Forecast of equipment industry is also very bright. Process of crystallizing through heat treatment at hundreds of degrees is a must for Oxide TFT process. Demand for this process was low for previous a-Si TFT, and Viatron and Terasemicon in Korea have unrivaled technologies in this area. As market demand is planning to be increased, many equipment businesses are preparing to enter into market for heat treatment equipment.

“Although there are a lot of difficulties in securing yields because Oxide TFT is sensitive to outside environment due to organic substances, it is at a condition where most of technology process is achieved. It will soon form 2 prominent technologies with LTPS boards as next generation board technologies.” said a person in this industry.

Staff Reporter Sung, Hyeonhee | sunghh@etnews.com