Samsung Advanced Institute of Technology developed high-crystalline Graphene coating silicon cathode material technology that has twice more of energy density than commonly-used lithium ion battery.

Result for this research was published as ‘Materialization of High-Capacity Lithium Ion Battery Using SiC-free Graphene Direct-Growth Silicon Cathode Material’ on online scientific journal Nature Communications on the 25th.

Lithium ion battery was first commercialized in 1991. Due to its limitation on cathode and anode materials, its development was focused on improvement of capacity with a basis on optimization of battery structure. But because capacity’s improvement was only twice better, there was a limitation on developing high-capacity and high-density battery relevant to growth of mobile equipments and Electric Cars market.

Recently development of high-capacity battery material that can fundamentally innovate capacity is speeding up. Although research on silicon, which can increase capacity ten times better than graphite that is currently being used as cathode material, is being actively progressed, there was a technical problem where age was rapidly decreasing due to repetition of battery’s charge and discharge.

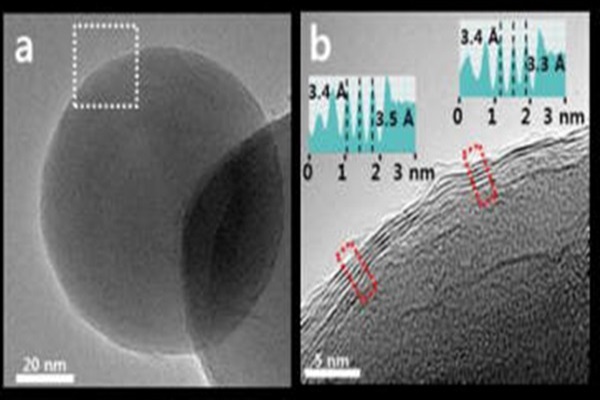

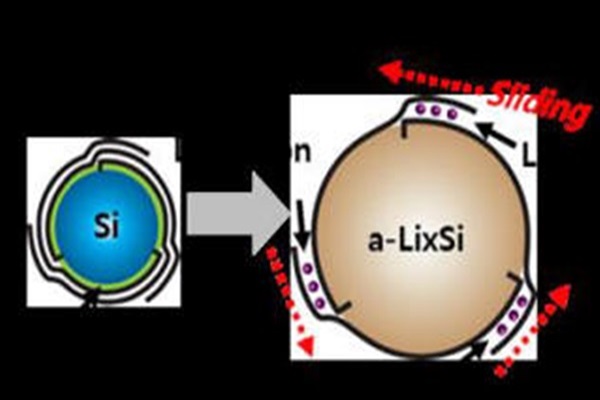

Samsung Advanced Institute of Technology developed high-capacity and highly durable cathode material that can solve this problem. By being the world’s first to apply Graphene that has high physical strength and conductivity onto silicon surface, research team was able to synthesize structure with Graphene layer that can prevent structure collapse due to volume expansion white charging and discharging.

It became world’s first to investigate a mechanism that increases durability while Graphene protective layer slides during volume expansion. This material has four times of capacity than graphite and it can give twice more of energy density if it is applied on commonly-used lithium ion battery.

Samsung Electronics announced that this technology was applied for total of 5 patents in the U.S., Europe, China, and Korea. “This technology greatly improves performance of lithium ion battery material by applying new high-crystalline synthesis method onto high-capacity silicon cathode. We are going to continually innovate this secondary battery technology corresponding to growth of mobile equipments and Electric Cars market.” Professional researcher Son In Hyuk of Samsung Advanced Institute of Technology, who is the first author of this thesis, said about how this research came about and how it will be in the future.

Samsung Advanced Institute of Technology also developed a technology that can control phonon characteristic in Graphene within the size of nanometer. This technology was published as ‘Control of Graphene Phonon within the Size of Nanometer’ on online scientific journal called Nature Communications. It was successful in creating a pure Graphene state within the size of nanometer by increasing the distance between Graphene and a board by colliding argon ion and Graphene.

It became the first to present a method to create pure Graphene area that has little interaction with a board within the size of nanometer, which is about a tenth of semiconductor’s line width. Through the measurement of local phone characteristic, it is estimated that basis for high-density semiconductor’s element’s design and analysis using Graphene hereafter is prepared.

Senior Reporter Kim, Seungkyu | seung@etnews.com