LG Display is expanding production capability for low power·high resolution oxide thin film transistor (TFT) panel. It is because Apple is putting oxide TFT panel into their next generation iPads. Oxide TFT reduces the power usage and is good for condensed products.

LG Display has begun on investment for the 8th generation (2200 x 2500mm) P8·P9 line for oxide TFT processing that is located in Paju. The scale size is 21,000 sheets per month with glass disks as standard. Some of the main equipment selections are made by the company.

LG Display has equipped facilities of oxide LCD panel in scale of 9000 sheets per month last year. With the expansion, they will be able to produce up to 30,000 sheets per month. They also have plan of expanding an additional 20,000 sheets next year. If it happens as it is scheduled, the 8th gen line will exceed the Japan SHARP’s production capability that is producing about 30,000 sheets per month.

A well-informed LG Display related official said, “Investment to produce 30,000 sheets next year’s second quarter have started. Apple is creating iPads with 12.9 inch display, which shows they are increasing the panel size. And because so, we are planning in expanding production rate as well.”

The reason why LG Display is expanding their oxide panel production line is because Apple has decided to use oxide panels in their future iPads and iMacs. Oxide TFT LCD has lower power base with ease to design slimmer and also excellent in touch sense than the previous a-Si TFT LCD.

Apple plans to obtain oxide TFT via LG Display, Samsung Display, and SHARP. Samsung Display recently secured production capability of 20,000 sheets per 5th gen (1100mm x 1300mm) line. Their goal is to expand 20,000 more so that they would have 60,000 producing capability by the end of the year. However, because it is 5th gen that has less extent, it has lower chamfer rate.

LG Display will put more gas on the pedal for the new investment in order to secure more production amount than other competing companies. Oxide can be produced from the previous a-Si TFT LCD production line so the investment cost is not that high. Also, the processing relatively simple which cuts down the production cost as well.

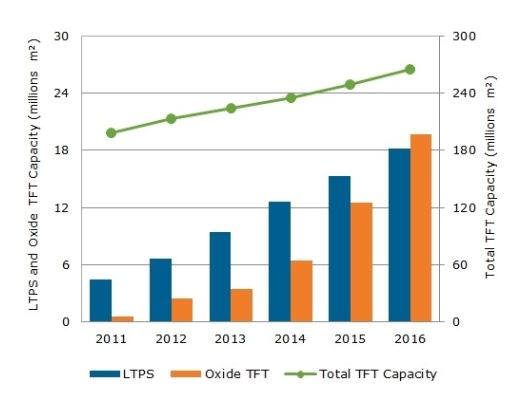

Industry expert said, “The companies have been having difficulty in improving harvesting rate due to stabilizing oxide problem but now much technically improvement has been made. Oxide will take its place with LTPS as main boarding technology soon enough.”

Staff Reporter Sung, Hyeonhee | sunghh@etnews.com