Domestic light emitting diode (LED) chip and package makers have rolled up their sleeves to dominate next-generation technologies for ‘white flip chip.’ While existing flip chip technologies are drawing attention for providing excellent light emitting function and slim design, white flip chip is evaluated as a further evolved version with the manufacturing process drastically reduced from the ones available in the market.

Having started flip chip technology application to TVs last year, Samsung Electronics is accelerating white flip chip LED development. LG Electronics is also promoting to apply white flip chip LED to their next TV models this year. Accordingly, competition over the global market dominance is forecast to intensify.

According to the industry on the 13th, Korea’s leading LED chip and package makers, such as Samsung Electronics and LG Innotek, are working on white flip chip LED development projects to strengthen their positions in the global LED market.

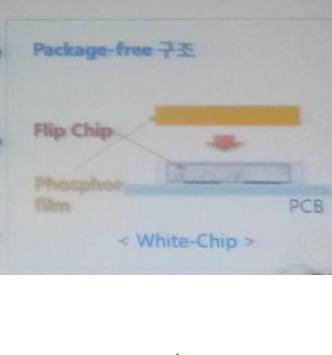

Flip chip LED is created by directly attaching LED chip electrodes to a printed circuit board (PCB) without any joint structures, such as metallic wire in the existing products. As it does not require a separate space for the wire connection, backlight unit (BLU) thickness is reduced considerably. For white flip chip LED, packaging stage using lead frame is omitted from the manufacturing process. As a result, a substantial cost reduction is possible.

Samsung Electronics applied a flip chip LED to direct BLU TV as the first in the world last year and is now developing the white flip chip LED. LG Electronics is also taking steps for applying white flip chip to its products this year.

“LG Electronics had planned to apply flip chip first and then to move to white flip chip. However, it recently decided to move directly to white flip chip LED in order to dominate the related markets,” said an industry source. He forecast, “LG Electronics will soon commence mass-production as optical conversion efficiency of phosphor and chip performance are improving rapidly.”

Samsung Electronics and LG Innotek started technology development earlier on, and thus have already produced considerable progresses. Both companies recognize white flip chip LED as a next-generation lighting technology. However, there are differences in the technology implementation. Samsung Electronics adopted a method to directly attach fluorescent film on to the surface of flip chip and LG Innotek opted for a method to mold up a chip using phosphor and then to cut up the molded piece.

“Both Samsung and LG are working under heavy security as they are developing next-generation leading technologies,” said the industry source. “In particular, white flip chip LED manufacturing process is very similar to semiconductor process. Therefore, by securing the technology swiftly, domestic companies will be able to use it as an ace up their sleeves in alleviating the threats from Chinese companies.”

Global lighting companies, such as those in the U.S., are also showing a high level of interest in white flip chip LED technology. They are discussing technological cooperation with Korean companies and requesting special lectures about this technology at the global LED lighting conferences.