Non-contact painting technology 'VSS transfer'

Implementation of color and design for phone cases, home appliances, etc.

No waste and significant reduction of process costs

A technology that can easily paint smartphone cases, home appliances, and interior and exterior materials for automobiles has been developed in Korea. It is under the spotlight whether this new technology that offers simple process and produces essentially no waste will be an alternative to the existing traditional painting methods such as spray or water transfer.

CrucialTec announced on the 28th that it has developed a technology to implement colors and designs on plastic, glass, and metal using water vapor pressure and air pressure.

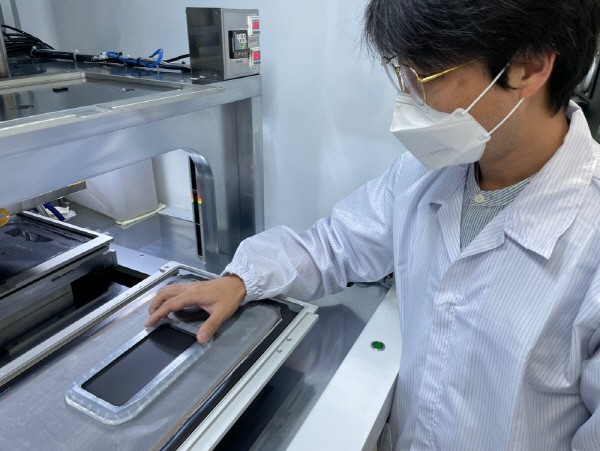

This technology is called 'Vacuum Steam Solution (VSS) transfer' and is characterized by applying heat and pressure to the ink-coated film in a non-contact manner to cover the object with ink.

Spraying paint or floating ink on water to apply color or pattern was mainly used when painting smartphone cases, helmets, and other parts.

However, this method requires large-scale facilities or manpower. A space of 300-400m and at least 10 people are required to equip one line for spray painting method.

It is inevitable to avoid producing a large amount of waste since the spray method collects paint discarded after cleaning with water, and water transfer moves ink by floating in water.

CrucialTec VSS simplifies the complicated process by painting like attaching a film to a case in a closed device.

In addition, the company explained that it only uses a small amount of water necessary to generate steam pressure and does not generate water-waste because it applies pressure only to the necessary parts and transfers the ink so that the ink in the film settles on the surface.

Yu-yong Lee, Vice President of CrucialTec, said, "Only the printed layer is transferred through the steam pressure in a vacuum state, so no contaminated water flows out. The facility is also an eco-friendly technology that costs only one-tenth of the investment cost of spraying.”

CrucialTecintroduced that it jointly developed VSS transcription technology with Japan'sYoshida Group. Yoshida is a company that supplies cases to luxury cosmetics companies in Europe, the United States, and Japan. It is regarded as one of the world's top-tier enterprise technology companies. CrucialTec, which supplies fingerprint recognition modules for smartphones, explained that it developed VSS transfer technology while researching how to effectively paint the fingerprint recognition button.

CrucialTec plans to promote full-scale commercialization as VSS shows excellent performance in painting curved three-dimensional objects. Keon-joon Ahn, CEO of CrucialTec, said, “I am convinced that VSS will become a game changer in an era where eco-friendliness is essential. We will promote the business of transferring smartphone cases and auto parts.”

By Staff Reporter Gun-il Yun (benyun@etnews.com)