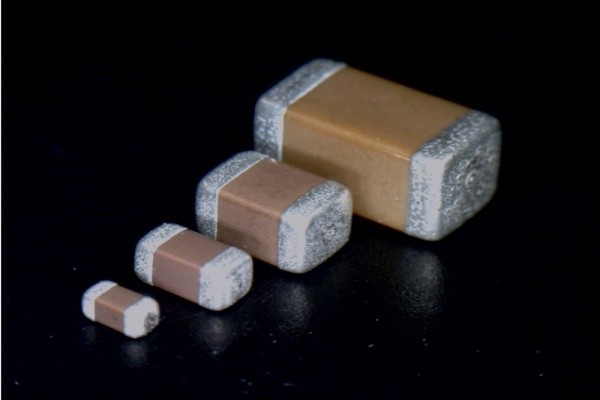

Amotech has developed new MLCCs (multi-layer ceramic capacitor) that can be used for cars and various industries. By developing a technology that maximizes stability while maintaining chip size, it will look to secure competitive edge in the next-generation MLCC market.

The company announced on Monday that it has developed new MLCCs. One of the new MLCCs has width and length of 0.6mm and 0.3mm respectively while the other MLCC has width and length of 2.0mm and 1.25mm respectively.

MLCC is a component that acts like a ‘dam’ and allows current to flow smoothly through circuits of electronic products. It also removes any unnecessary noise that can occur while current flows through circuits.

Because it is an important component of electronic devices, it is used for various IT products such as smartphones and home appliances. Due to a recent boom in the markets for electric vehicles and autonomous vehicles, MLCCs are also starting to be used widely by the automotive market. Because cars have to operate while withstanding extreme environment factors, MLCCs with high reliability that can perform its functions even under high temperature or voltage are receiving attention.

In order to meet such demands, Amotech had been concentrating on developing a technology that can improve stability while making chip size smaller.

In case of 1005 MLCCs, they have a rated voltage of 16V that is about 10 volts higher than MLCCs that are currently used. Due to a drastic improvement in rated voltage, lifespan of the capacitors is also increased by 40 times.

They also satisfy ‘X7R’ level that is given to chips that can perform their functions without any issue even under an environment with high temperature. They are extremely stable even when they experience a sudden increase in temperature.

“In the past, chips were made little bit bigger or had their specifications lowered in order to manufacture chips with high capacity.” said a representative from Amotech. “However, our products have drastically improved reliability and lifespan while maintaining chip size.”

In order to manufacture MLCCs with high reliability, the company has developed various technologies such as dielectric composition, nanopowder dispersion, precise molding, and printing and stacking technologies.

Its new MLCCs are already recognized for their excellent performance as they had gone through reliability tests by related domestic and foreign companies.

Amotech plans to focus on R&D and develop various MLCCs that are even smaller in size and satisfy difficult criteria at the same time.

“We are also accelerating development process of X5R and X6S chips that are mostly used for smartphones.” said a representative from Amotech. “We are preparing to finish the process that has taken over three years and we are in contact with major telecommunications equipment manufacturers in South Korea and other countries.”

The representative also added that the company plans to supply MLCCs to other customers as well such as ones in the automotive market.

Staff Reporter Kang, Hyeryung | kang@etnews.com